2025 Top Innovations in Tube Laser Technology for Precision Manufacturing

In recent years, tube laser technology has emerged as a pivotal innovation in the field of precision manufacturing, driving efficiency and enhancing productivity across various industries. As reported by industry analysts, the global market for laser cutting technology is expected to reach USD 9.95 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.5%. This growth is significantly influenced by the increased adoption of tube laser systems, which facilitate greater design flexibility and precision in the manufacturing processes.

The advancements in tube laser capabilities offer remarkable benefits, such as the ability to cut complex geometries with high accuracy and minimal material waste. According to a recent study by the International Laser Manufacturing Association, tube laser cutting can increase production efficiency by up to 30%, making it an attractive solution for fabricators seeking both cost savings and improved output. In this context, the year 2025 is poised to showcase a series of groundbreaking innovations within tube laser technology that promise to further revolutionize precision manufacturing, enabling industries to meet the ever-evolving demands of a competitive market landscape. As we explore the top innovations on the horizon, it is essential to understand how these advancements will shape the future of manufacturing, driving both quality and efficiency to new heights.

The Evolution of Tube Laser Technology in Precision Manufacturing

The evolution of tube laser technology has dramatically transformed the landscape of precision manufacturing. In the early stages, traditional cutting methods relied heavily on mechanical processes, which often resulted in inefficiencies and limitations in design complexity. However, the advent of laser technology introduced a level of precision that was previously unattainable. Over time, advancements in laser power, beam quality, and control systems have led to increased cutting speeds and improved edge quality, making tube laser systems indispensable in modern manufacturing environments.

As industries continue to demand more intricate and customized solutions, tube laser technology has adapted to meet these challenges. The integration of automation and smart manufacturing principles has further enhanced its capabilities, allowing for real-time monitoring and adjustments during the cutting process. This not only boosts productivity but also ensures higher levels of accuracy and repeatability in the final products. Furthermore, developments in software for design and simulation have streamlined the workflow, enabling manufacturers to optimize their designs before actual production begins. Overall, the trajectory of tube laser technology reflects a commitment to innovation and efficiency, positioning it as a cornerstone of precision manufacturing for years to come.

Key Performance Metrics for 2025 Tube Laser Systems

As we look towards 2025, the advancements in tube laser technology promise to revolutionize precision manufacturing. Key performance metrics for tube laser systems will focus on efficiency, precision, and flexibility. Recent industry reports indicate that the demand for high-precision laser cutting systems is expected to grow by 15% annually. This growth underscores the importance of optimizing laser power and cutting speed, as these elements significantly impact productivity and material utilization. Systems with energy-efficient lasers that maintain high cutting speeds are anticipated to lead the market by minimizing operational costs while maximizing output quality.

Manufacturers should also monitor metrics such as beam quality and cutting accuracy. Enhanced beam quality allows for finer cutting capabilities, which is crucial for intricate designs in sectors ranging from aerospace to automotive. Moreover, innovations in control technology are improving real-time adjustments during the cutting process, leading to tighter tolerances and less waste. Reports show that systems achieving +/- 0.01mm precision are becoming the benchmark in the industry.

Tips: To ensure optimal performance from tube laser systems, manufacturers should invest in regular maintenance and software updates. Implementing predictive maintenance strategies can also reduce downtime significantly. Additionally, exploring automation integration can streamline operations, enhancing the overall efficiency of tube laser applications.

Innovative Features Enhancing the Precision of Tube Lasers

The evolution of tube laser technology has significantly enhanced the precision capabilities of manufacturing processes, particularly in industries requiring intricate designs and tight tolerances. According to a recent market report, the global tube laser market is projected to reach approximately $3.69 billion by 2025, growing at a CAGR of 6.4%. This growth is driven by innovative features such as advanced beam shaping, dynamic focus adjustment, and improved cutting algorithms. These enhancements allow manufacturers to achieve finer edge quality and reduced heat-affected zones, facilitating the fabrication of complex components with minimal thermal distortion.

In addition to these technological advancements, automation integration and real-time monitoring systems play a crucial role in elevating the precision of tube laser operations. Smart sensors and artificial intelligence algorithms enable manufacturers to adapt cutting parameters on-the-fly, ensuring optimal performance and accuracy. A research study highlights that implementing these innovations can improve production efficiency by up to 30%, while simultaneously reducing material waste. As industries continue to embrace tube laser technology, the ability to deliver high precision at scale will remain a pivotal factor in achieving competitive advantage in the manufacturing landscape.

2025 Top Innovations in Tube Laser Technology for Precision Manufacturing

This chart illustrates the advancements in tube laser technology innovations contributing to precision manufacturing in 2025. The data reflects the percentage improvement across different innovative features.

Market Demand and Growth Projections for Tube Laser Technology

The demand for tube laser technology in precision manufacturing is projected to experience significant growth in the coming years. As industries continue to embrace automation and the principles of Industry 4.0, the capabilities offered by advanced tube laser systems are becoming increasingly vital. These systems allow for greater flexibility, improved quality, and reduced lead times in manufacturing processes, making them attractive to a wide range of sectors including automotive, aerospace, and construction. The ability to cut complex shapes with high precision is a key driver, as manufacturers look to enhance product design and efficiency.

Market analysts anticipate that advancements in tube laser technology will also be fueled by ongoing innovations in processing speed and material compatibility. As manufacturers face pressures to lower costs while maintaining high production standards, the effectiveness of tube lasers in efficiently processing various materials—such as metals, plastics, and composites—positions them as a crucial tool in modern manufacturing. Furthermore, as companies prioritize sustainable practices, the energy efficiency of tube laser systems is expected to align with their objectives, resulting in a dual benefit of environmental responsibility and cost reduction. Overall, the future of tube laser technology appears promising, with substantial potential for growth driven by evolving market demands.

| Innovation Type | Description | Market Demand Growth (%) | Projected Market Size (Million USD) | Key Benefits |

|---|---|---|---|---|

| High-Power Fiber Lasers | Enhanced precision and speed for cutting various materials. | 15% | 1,200 | Reduced energy costs and faster processing times. |

| 3D Laser Cutting | Ability to cut complex shapes in three dimensions. | 20% | 800 | Increased design flexibility and material usage efficiency. |

| Automated Laser Systems | Fully automated solutions for enhanced productivity. | 18% | 950 | Reduction in labor costs and human error. |

| Advanced Beam Manipulation | Technologies to adjust beam shape and focus dynamically. | 10% | 600 | Improved cutting quality and surface finish. |

| Hybrid Laser Systems | Combining different laser technologies for versatility. | 12% | 750 | Flexibility in handling various materials. |

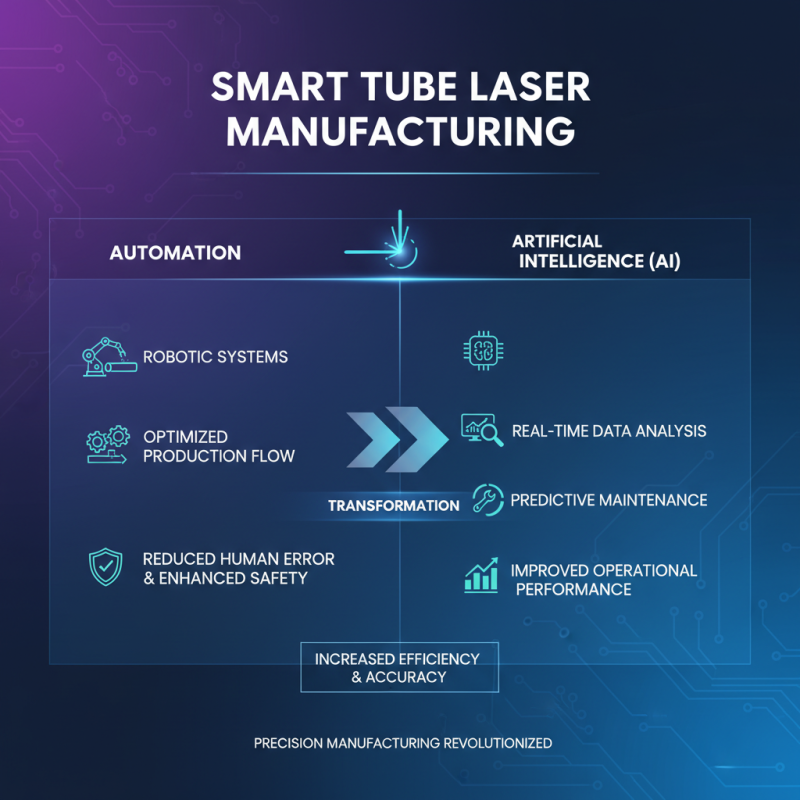

Impact of Automation and AI on Tube Laser Manufacturing Processes

The integration of automation and AI in tube laser manufacturing is transforming precision manufacturing processes, enabling increased efficiency and accuracy. Automation simplifies complex tasks such as cutting, bending, and welding by employing robotic systems that work alongside tube lasers. These systems optimize production flow, reduce human error, and enhance overall safety. With the capabilities of AI, manufacturers can analyze vast amounts of data in real time, predicting maintenance needs and improving operational performance.

Tips: To maximize the benefits of automation and AI, companies should invest in training employees to work effectively with new technologies. By fostering a culture of continuous learning, manufacturers can ensure their workforce is equipped to leverage advancements fully. Additionally, regular software updates and system audits can help maintain the efficiency of automated processes.

AI-powered systems can also refine design processes by simulating various parameters and outcomes before physical production begins. This reduces material waste and allows for more precise adjustments to be made on the fly, ensuring that products meet exact specifications. As these technologies evolve, businesses that embrace these innovations will be well-positioned to lead the market in precision manufacturing.

Related Posts

-

Top 10 CNC Cutting Techniques for Precision and Efficiency in Manufacturing

-

Top 10 CNC Fiber Laser Cutting Machines for Precision and Efficiency

-

Top 10 CNC Laser Cutting Machines for Precision Fabrication in 2023

-

Why Tube Laser Cutting is Essential for Modern Manufacturing Efficiency: Key Stats Inside

-

2025 Top 5 Laser Tables for Precision Cutting and Engraving Industry Insights

-

The Ultimate Guide to Choosing the Right Laser Tube for Your Engraving Projects

Machine models and specifications are subject to change without notice.