10 Best Laser Cutting Tables for Precision and Efficiency in 2023

In recent years, the demand for precision and efficiency in manufacturing processes has led to a significant rise in the popularity of laser cutting technology. According to a report by MarketsandMarkets, the global market for laser cutting machines is projected to reach USD 4.1 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.4%. This growth emphasizes the critical role that laser cutting tables play in enhancing productivity, accuracy, and cost-effectiveness across various industries, including automotive, aerospace, and metal fabrication.

Laser cutting tables have evolved to meet the escalating demands of modern production environments. With advancements in technology, these tables are now capable of handling a wide range of materials and thicknesses with remarkable precision. Research from Grand View Research indicates that innovative developments in laser cutting technology are becoming increasingly essential as manufacturers seek to improve their operational efficiency and reduce waste. As laser cutting tables become more sophisticated, they offer features such as automated setup, improved safety mechanisms, and integration with CAD software, thereby streamlining the entire cutting process.

In light of these trends, selecting the right laser cutting table is crucial for businesses aiming to stay competitive in an ever-evolving market. This article delves into the ten best laser cutting tables of 2023, highlighting their features and benefits to assist manufacturers in making informed decisions that align with their operational goals and budgetary constraints.

Overview of Laser Cutting Tables and Their Importance

Laser cutting tables have revolutionized the manufacturing and crafting industries, providing unparalleled precision and efficiency in cutting a variety of materials. These tables utilize high-powered lasers to achieve clean cuts and intricate designs that traditional cutting methods simply cannot match. The importance of laser cutting tables lies in their ability to enhance productivity while ensuring high-quality results, making them indispensable tools for both small workshops and large-scale production facilities.

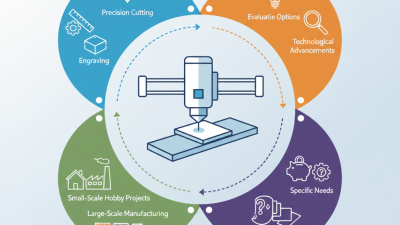

When selecting a laser cutting table, it’s crucial to consider factors such as the size of the work area, the types of materials you'll be cutting, and the power of the laser. Additionally, look for features that improve usability, such as user-friendly interfaces and software compatibility. Investing in a reliable machine can pay off significantly in terms of time saved and precision improved.

Tips: Always keep safety in mind by using proper ventilation and protective gear when operating a laser cutting table. Regular maintenance is also essential to ensure consistent performance; this includes cleaning the laser lens and checking for any wear on the components. If you’re new to laser cutting, starting with simple projects can help you familiarize yourself with the technology before tackling more complex designs.

Criteria for Selecting the Best Laser Cutting Tables in 2023

When selecting the best laser cutting tables in 2023, several key criteria should guide your decision-making process. First and foremost, precision is paramount. A good laser cutting table must deliver consistent and accurate cuts across various materials. This includes evaluating the laser's wattage and beam quality, as these factors directly influence the cutting capabilities and the quality of the finished product. Additionally, the table should be compatible with the materials you intend to work with, such as wood, acrylic, or metal, ensuring versatility in your projects.

Another essential consideration is efficiency. A laser cutting table's design and features significantly impact its operational speed and ease of use. Look for tables with advanced automation features, such as intuitive control systems and software compatibility that can streamline the workflow. Moreover, the construction of the table itself should promote stability and reduce vibration, contributing to cleaner cuts and minimizing material wastage. Maintenance and support options are also vital; a user-friendly design with easy access to components can save time and enhance productivity in the long run. By focusing on precision and efficiency, you can choose a laser cutting table that meets your specific needs and enhances your crafting experience.

Top 10 Laser Cutting Tables for Precision and Efficiency

In the ever-evolving landscape of manufacturing and design, the demand for precision and efficiency in laser cutting technology has surged dramatically. Recent industry reports indicate that the global laser cutting market is projected to reach approximately $8.8 billion by 2026, growing at a compound annual growth rate (CAGR) of around 5.5% from 2021 to 2026. This growth is fueled by advancements in laser technology, allowing for more intricate designs and significantly reduced operational costs.

The top laser cutting tables of 2023 are specifically engineered to maximize both precision and efficiency, catering to the needs of industries ranging from aerospace to textiles. Integrating features such as multi-axis capabilities and advanced cooling systems, these tables not only enhance the accuracy of cuts but also increase throughput, allowing users to complete projects in shorter timeframes.

According to a study by the International Journal of Advanced Manufacturing Technology, operators using high-precision laser cutting tables reported a 30% increase in production efficiency and a reduction of material waste by up to 20%. This level of performance is critical as businesses strive to adopt more sustainable practices while maintaining competitive advantages in the marketplace.

As manufacturers continue to seek out solutions that combine speed with meticulousness, the best laser cutting tables of 2023 stand out as essential investments. With their ability to process a wide range of materials including metals, plastics, and wood, these machines are setting a new standard in the industry, pushing the boundaries of what is possible in precision engineering and design.

Comparative Analysis of Features and Pricing

When selecting a laser cutting table, it's essential to conduct a comparative analysis of the features and pricing associated with the top models on the market. Precision and efficiency are critical factors, but potential buyers should also consider variables such as cutting area size, maximum material thickness, and speed of operation. For instance, some tables may offer larger cutting areas suitable for industrial applications, while others might focus on compact designs ideal for small workshops. Additionally, features such as adjustable power settings, cooling mechanisms, and user-friendly software can significantly impact both the performance and overall user experience.

Pricing is another critical aspect of this comparative analysis. Laser cutting tables vary widely in cost depending on their capabilities and build quality. It's vital to evaluate the return on investment by considering not only the initial purchase price but also the long-term operational costs, which include maintenance, electricity consumption, and potential replacement parts. Buyers should look for a balance between affordability and functionality, ensuring that the chosen model meets their specific needs without overspending. By carefully assessing features and pricing, consumers can make informed decisions that enhance their productivity and output quality in 2023.

User Reviews and Recommendations for Each Table

When selecting the best laser cutting tables for precision and efficiency, user reviews play a crucial role in guiding potential buyers. Many users emphasize the importance of build quality and stability. A sturdy table not only enhances cutting precision but also minimizes vibration, which can affect the integrity of detailed cuts. Users often recommend tables that feature adjustable heights and ample workspace, allowing flexibility for various projects while maintaining comfort during long working sessions.

Efficiency is another key aspect highlighted in user recommendations. Many individuals share their experiences with different table sizes, noting that larger tables can accommodate extensive materials and reduce the need for frequent repositioning. Positive feedback also often points to tables equipped with features like integrated ventilation systems and effective software compatibility. Users appreciate tables that make it easy to switch between various materials, enhancing workflow and ensuring project timelines are met without unnecessary delays. Overall, user insights provide valuable information for those looking to invest in a laser cutting table that combines both precision and efficiency in their workspace.

10 Best Laser Cutting Tables for Precision and Efficiency in 2023

Related Posts

-

2025's Top 5 Laser Cutting Tables: Unleashing Precision and Innovation

-

The Ultimate Guide to Choosing the Right Laser Tube for Your Engraving Projects

-

Exploring the Future: How Laser Machines Are Revolutionizing Modern Manufacturing Techniques

-

What is a CNC Laser Cutter and How Does it Work for Your Projects

-

Top 10 Tips for Perfect Laser Cutting and Bending Techniques You Need to Know

-

How to Choose the Right Laser CNC Machine for Your Projects

Machine models and specifications are subject to change without notice.