How to Choose the Best CNC Cutting Machine for Your Projects

In the rapidly evolving landscape of manufacturing and fabrication, the choice of equipment can significantly influence productivity and precision. Among the various tools available, the CNC cutting machine stands out as a cornerstone technology for numerous industries, from automotive to aerospace. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach approximately $117 billion by 2026, with CNC cutting machines playing a pivotal role in this growth. The increasing demand for automation and precision engineering has led to an uptick in the adoption of CNC cutting machines, which boast capabilities such as intricate design handling and high-efficiency production processes.

When selecting the best CNC cutting machine for specific projects, it is crucial to evaluate several factors, including material compatibility, cutting precision, and production volume. A recent study by Grand View Research noted that advancements in CNC technology, including the integration of AI and IoT capabilities, are reshaping the industry by enhancing operational efficiency and reducing downtime. Understanding these trends and their application to your particular needs will ensure that you make an informed decision, enabling your projects to achieve the desired quality and cost-effectiveness. As we delve deeper into the intricacies of CNC cutting machines, we aim to provide a comprehensive guide to equip you with the knowledge necessary for this vital investment.

Understanding the Basics of CNC Cutting Machines

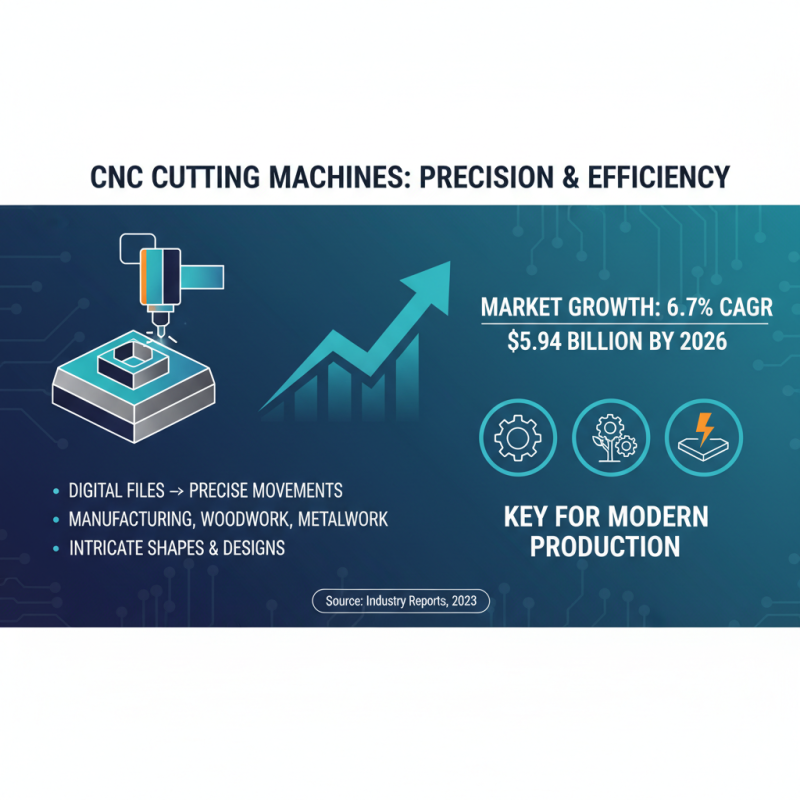

CNC (Computer Numerical Control) cutting machines are essential tools in various industries, including manufacturing, woodworking, and metalwork. Understanding the basics of these machines is crucial for selecting the best one for your projects. CNC cutting machines operate by converting digital files into precise movements that guide cutting tools to produce intricate shapes and designs. According to industry reports, the global CNC cutting machine market is expected to grow at a compound annual growth rate (CAGR) of 6.7%, reaching $5.94 billion by 2026, highlighting the increasing demand for precision and efficiency in production.

When choosing a CNC cutting machine, it is vital to consider key factors such as the type of materials you will be working with, the size and complexity of the cuts needed, and the machine’s overall capabilities. Different machines cater to specific materials—such as wood, metal, or plastics—so ensure that the machine you choose aligns with your intended use. Furthermore, consider the machine's software compatibility and ease of use, as efficient software can streamline your workflow significantly.

**Tips:** Before making a purchase, assess your project requirements thoroughly. Seek demonstrations or trial periods to evaluate how a specific machine handles your materials. Consulting with industry experts can also provide valuable insights that help in making an informed decision, ensuring that the CNC cutting machine you choose maximizes your productivity and meets your project needs.

Defining Your Project Requirements and Material Types

When selecting a CNC cutting machine for your projects, the first step is to clearly define your project requirements. Consider the complexity of the designs you intend to create, as well as the precision level needed. For intricate designs involving fine details, a machine with higher resolution capabilities will be vital. Understanding the scale of your projects is equally important; larger machines are better suited for extensive work while compact models could be ideal for smaller tasks.

Additionally, the types of materials you'll be working with greatly influence your choice of a CNC cutting machine. Different machines are optimized for specific materials such as wood, metal, or plastics. For instance, if your projects involve working with hardwood or soft metals, ensure that the machine has the appropriate cutting tools and power settings.

Tips: Always evaluate the thickness and density of your materials before making a decision—some machines may struggle with harder or thicker substrates. It's also a good idea to consider the versatility of the machine. Investing in a model that can handle a variety of materials expands your project possibilities and enhances long-term usability. Lastly, think about the software compatibility of the machine, as this will affect how easily you can design and execute your projects.

Comparing Different Types of CNC Cutting Machines

When selecting the best CNC cutting machine for your projects, it's crucial to compare the different types available, as each offers unique advantages tailored to specific needs. The primary categories are laser cutting machines, plasma cutters, and waterjet cutters. Laser cutting machines are renowned for their precision and ability to cut intricate designs in materials such as wood, metal, and plastic. They excel in applications requiring high detail, making them ideal for decorative projects or intricate parts manufacturing.

On the other hand, plasma cutters provide a faster cutting speed and are well-suited for thicker metals. They employ a high-velocity jet of ionized gas to melt and cut through conductive materials, making them perfect for industrial settings where speed is essential. Lastly, waterjet cutting machines utilize high-pressure jets of water mixed with abrasive materials to cut through a variety of substances, including metals, glass, and stone, without altering their intrinsic properties. This versatility makes waterjet cutters an excellent choice for projects requiring complex shapes without thermal damage. Each type of CNC cutting machine serves distinct purposes, so understanding their strengths will help you make an informed decision for your specific applications.

How to Choose the Best CNC Cutting Machine for Your Projects - Comparing Different Types of CNC Cutting Machines

| CNC Cutting Machine Type | Material Compatibility | Max Cutting Thickness | Precision | Cost Range |

|---|---|---|---|---|

| Laser Cutting Machine | Metal, Wood, Acrylic | 0.1 - 20 mm | ±0.05 mm | $5,000 - $100,000 |

| Plasma Cutting Machine | Metal, Steel, Aluminum | 1 - 100 mm | ±0.5 mm | $3,000 - $50,000 |

| Waterjet Cutting Machine | Metal, Glass, Stone | 1 - 200 mm | ±0.1 mm | $25,000 - $500,000 |

| CNC Router | Wood, Plastic, Composites | 0.1 - 50 mm | ±0.2 mm | $2,000 - $30,000 |

Evaluating Key Features and Specifications

When selecting the best CNC cutting machine for your projects, it's essential to evaluate key features and specifications that align with your specific needs. One crucial aspect to consider is the cutting accuracy, which is typically measured in microns. According to industry data, machines with a precision level of ±0.01 mm are widely preferred for intricate and detailed designs. This level of accuracy ensures that even the most complex projects can be executed with precision, minimizing the need for rework.

Another significant specification to consider is the machine's cutting speed and power. Reports indicate that machines with a power output of at least 1,500 watts can handle a broader range of materials and thicknesses, which is particularly beneficial for versatile applications. Additionally, a cutting speed of over 10 meters per minute is ideal for high-production environments, allowing businesses to maximize their productivity without compromising on quality. Understanding these specifications will help you make an informed decision when investing in a CNC cutting machine tailored to your project's requirements.

Budgeting and Cost Considerations for CNC Machines

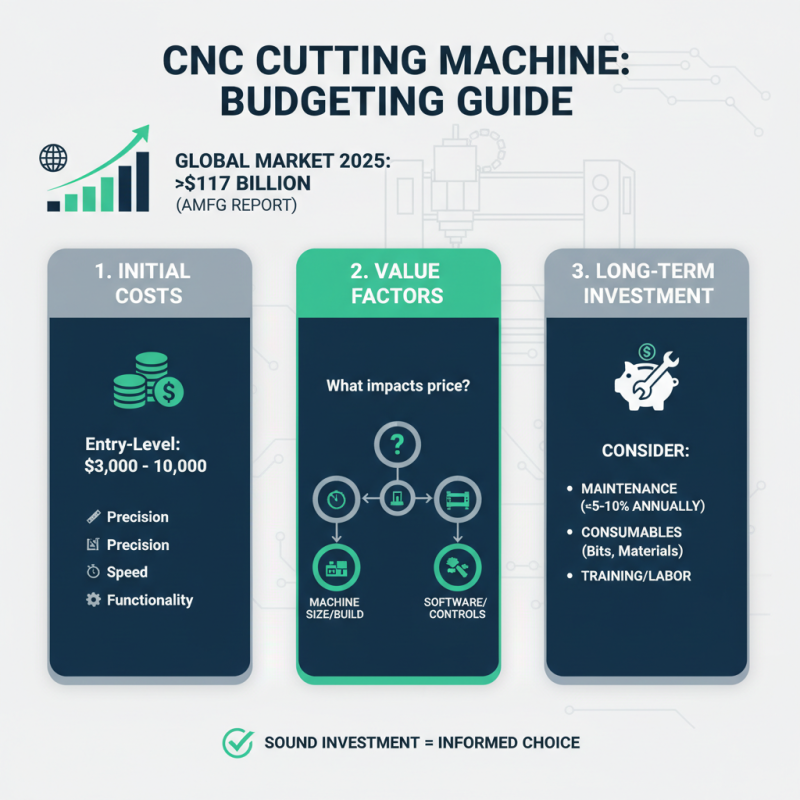

When selecting a CNC cutting machine for your projects, budgeting and cost considerations are crucial to ensure you make a sound investment. According to a report by AMFG, the global CNC machine market is expected to reach approximately $117 billion by 2025, emphasizing the significant financial commitments involved. The first step in budgeting is to understand the initial costs, which can range from a few thousand dollars for entry-level machines to upwards of $100,000 for high-end models. This price variation typically reflects differences in precision, speed, and functionality that can profoundly impact project outcomes.

Beyond the initial purchase price, it's essential to assess the total cost of ownership. This includes maintenance expenses, consumables, and any software required for operation. A survey by the Association for Manufacturing Technology (AMT) found that ongoing costs can represent up to 20-30% of the initial investment annually. Therefore, understanding the complete financial landscape—factoring in potential downtimes and operational efficiencies—can provide insights into the long-term viability of the machine within your specific operational context. Investing time to analyze these aspects will ultimately lead to a more informed decision that aligns with your project needs and budget constraints.

Related Posts

-

Top 10 Benefits of Alpha Laser Technology You Need to Know

-

What is a CNC Laser Cutter and How Does it Work for Your Projects

-

How to Choose the Right Laser Marking Machine for Your Business Needs

-

Top 5 Reasons to Invest in a CNC Laser Cutter for Your Business

-

Exploring the Future: How Laser Machines Are Revolutionizing Modern Manufacturing Techniques

-

Top 10 CNC Fiber Laser Cutting Machines for Precision and Efficiency

Machine models and specifications are subject to change without notice.