How to Choose the Best Fiber Laser Engraver for Your Needs?

When selecting a fiber laser engraver, understanding your specific needs is essential. Industry expert John Smith, who has over a decade of experience, emphasizes, "Choosing the right fiber laser engraver can make or break your project." With numerous options available, it’s easy to feel overwhelmed.

Different projects require different capabilities. For example, engraving metals needs more power compared to wood or acrylic. A fiber laser engraver can vary in specifications. You must consider wattage, speed, and precision. Each detail influences the outcome significantly. Many users forget to analyze their primary tasks. This oversight can lead to regrettable purchases.

Investing in the right fiber laser engraver means you’ll enhance your productivity. However, if not chosen wisely, you may end up with equipment that doesn’t serve your needs. Realizing this before purchasing is crucial. Understanding your project demands is vital to making an informed decision. Each choice reflects your commitment to quality and craftsmanship.

Understanding Fiber Laser Engraving Technology

Fiber laser engraving technology has gained popularity in various industries. This method uses highly focused beams of light to engrave or cut materials. The precision offered by fiber lasers is unmatched. It allows for intricate designs on metals and plastics. Users can achieve detailed patterns that are hard to replicate with other methods.

When considering fiber laser engravers, understanding their operation is crucial. They work by heating the material to create a permanent mark or cut. This technology excels in speed and efficiency. However, it may require a learning curve for beginners. Certain materials may react differently, and users need to adjust settings accordingly. Experimentation is key. Some surfaces might not engrave as expected. Patience is vital during the setup phase.

Selecting the right engraver involves considering the applications you have in mind. What materials will you work with? How thick are they? Different models address distinct needs. Some may be better suited for detailed work, while others handle larger volumes more efficiently. Reflecting on your specific requirements will help in making a wise choice.

Key Features to Consider in Fiber Laser Engravers

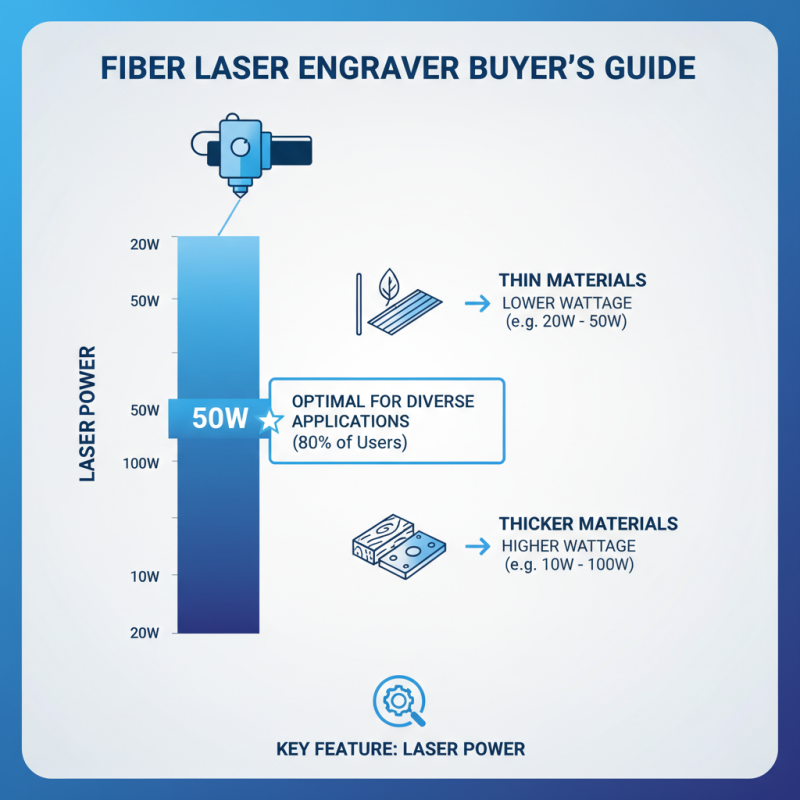

When selecting a fiber laser engraver, several key features should guide your decision. The laser power is crucial. Typically, the power ranges from 20W to 1000W. For thin materials, lower wattage may suffice, but thicker materials require higher power levels. Reports indicate that 80% of users find that 50W is optimal for diverse applications.

Next, consider the engraving speed. Many models offer speeds starting from 6000 mm/s. Faster speeds can significantly boost productivity. However, this feature comes with trade-offs. High speed may compromise engraving quality on intricate designs. According to industry data, a good balance is essential for detailed work.

Another critical aspect is the software compatibility. Most fiber laser engravers now support various design formats. A device that seamlessly integrates with the most commonly used graphic design software can save time and reduce errors. Flexibility in software can elevate user experience. Yet, not all machines deliver the same level of software integration. Be sure to verify these details. A more expensive option doesn’t always mean superior features. Often, users face challenges with feature overlaps and unnecessary complexity. Choosing wisely means assessing your specific needs against what is available on the market.

Evaluating Your Material Compatibility for Laser Engraving

When choosing a fiber laser engraver, material compatibility is key. Different materials react uniquely to laser engraving. Metals such as stainless steel and aluminum yield excellent results. In contrast, wood and acrylic require less intense settings. Understanding the material's properties can lead to better engraving outcomes.

Industry reports show that approximately 70% of users experience issues due to improper material choice. For instance, engraving on painted surfaces can lead to uneven results. Also, some materials may produce toxic fumes. It’s vital to assess whether the chosen laser can handle specific materials safely and effectively.

Testing is essential. Run trial engravings on scrap pieces first. Pay attention to depth and clarity. Sometimes, expected results may not match reality. Adjusting speed and power settings can lead to improved outcomes. Regularly reflecting on these experiments can enhance your engraving skills and help avoid costly mistakes.

Material Compatibility for Fiber Laser Engraving

Assessing Budget and Price Range for Fiber Laser Engravers

When considering a fiber laser engraver, budget plays a crucial role. Prices typically range from $5,000 to over $25,000, depending on the machine's features and capabilities. A report from Research and Markets states that the global laser engraving market is projected to grow at a CAGR of 8.5%. This increase reflects the rising demand for precision engraving across various industries.

Investing in a fiber laser may seem daunting. However, understanding the features essential for your business can help narrow your choices. A basic model might suffice for hobbyists. Advanced machines with higher wattage are necessary for commercial applications. The right balance between cost and functionality is vital. Explore models with warranties and customer support, as these factors often indicate quality.

Many buyers overlook long-term operational costs. Maintenance and consumables can add up significantly. Setting a budget also means considering these ongoing expenses. You may find that larger initial investments yield better efficiency and longevity. Therefore, a comprehensive assessment of both upfront and ongoing costs is essential.

Exploring Customer Reviews and Manufacturer Reputation

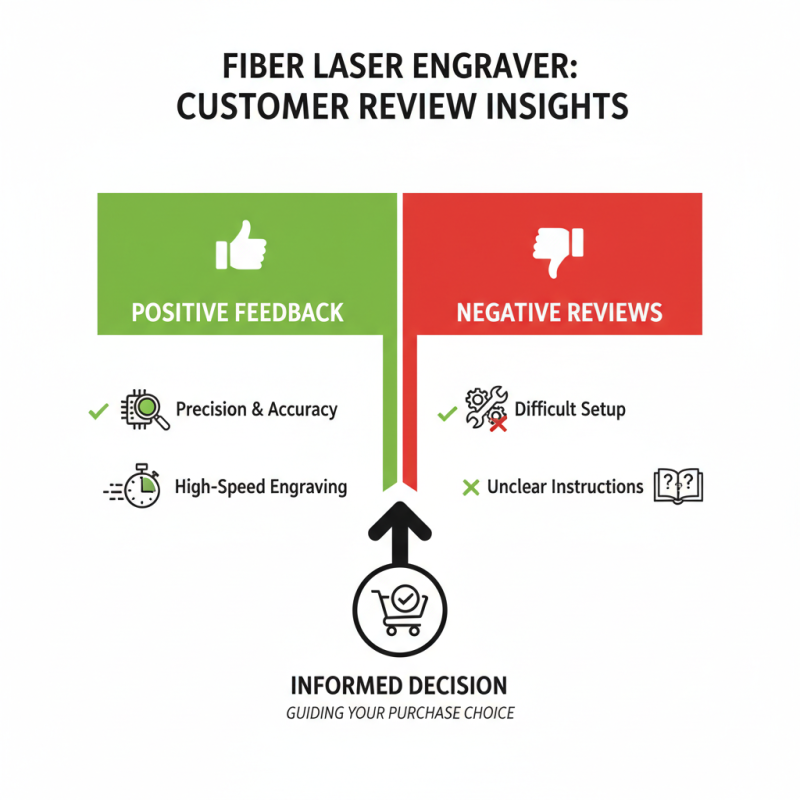

When choosing a fiber laser engraver, customer reviews offer valuable insights. Many users share their experiences online. Positive feedback often highlights precision and speed, essential for quality engraving. Negative reviews may point to difficulties in setup or instruction clarity. These insights can guide your decision.

Manufacturer reputation also plays a crucial role. A reliable brand is more likely to provide quality support and durable equipment. Investigate how long the company has been in the industry. Longevity often indicates stability. Additionally, assess their response to customer inquiries. Slow replies can be a red flag.

Sometimes, reviews can be misleading. A few satisfied customers may bias ratings. Look for patterns in feedback. Are there common issues reported by multiple users? This helps in making an informed choice. Engaging with online forums can also provide firsthand information. Remember, not all reviews reflect true user experience.

Related Posts

-

Top 5 Reasons to Invest in a CNC Laser Cutter for Your Business

-

Top 10 CNC Laser Cutting Machines for Precision Fabrication in 2023

-

How to Choose the Best CNC Cutting Machine for Your Projects

-

What is a Laser Cutting Machine and How Does it Work for Your Projects

-

Exploring the Future: How Laser Machines Are Revolutionizing Modern Manufacturing Techniques

-

How to Choose the Right Fiber Laser Cutting Machine?

Machine models and specifications are subject to change without notice.