How to Choose the Right Laser Machine for Your Business Needs

When it comes to selecting the right laser machine for your business needs, the decision carries significant weight in determining the efficiency and quality of your production processes. Laser machines are versatile tools that can enhance capabilities across various industries, from manufacturing to crafting and signage. However, with a plethora of options available, understanding how to assess your unique requirements is crucial to making an informed choice.

This guide aims to help you navigate the factors to consider before investing in a laser machine. Key considerations include the specific applications you intend to use the machine for, the materials you will work with, and the desired output quality. By clarifying your business goals and understanding the different features available in laser machines, you can select a solution that not only meets your immediate needs but also supports future growth and scalability.

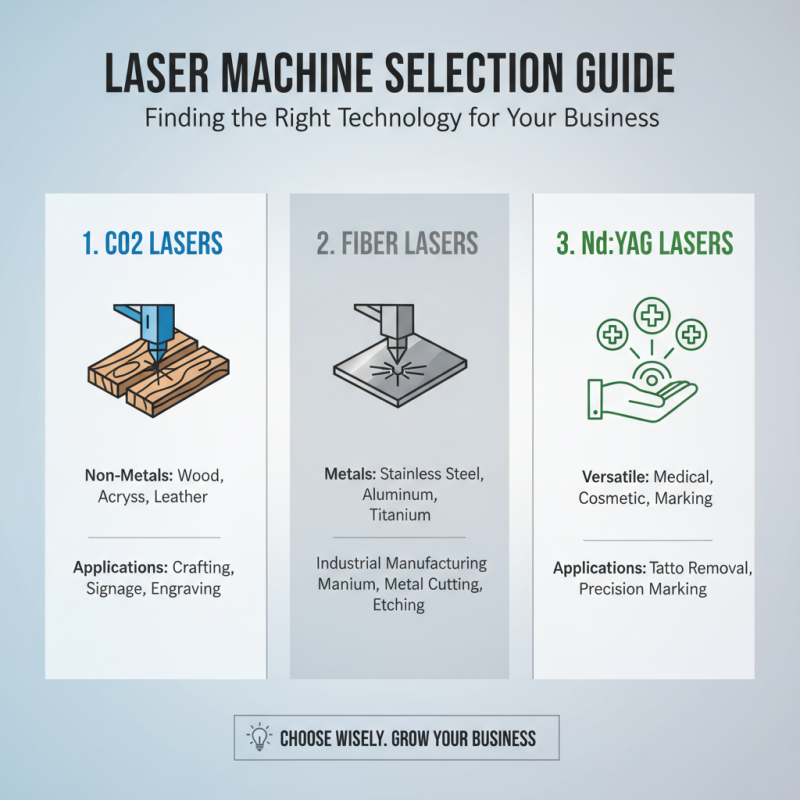

Understanding Different Types of Laser Machines and Their Applications

When selecting the right laser machine for your business, it's crucial to understand the different types of laser technology and their specific applications. There are primarily three categories of laser machines: CO2 lasers, fiber lasers, and Nd:YAG lasers. CO2 lasers are ideal for cutting and engraving non-metal materials like wood, acrylic, and glass, making them perfect for craft businesses and signage. Fiber lasers, on the other hand, are more suited for working with metals such as stainless steel and aluminum, which makes them a preferred choice in industrial manufacturing. Lastly, Nd:YAG lasers offer versatility and are commonly used in medical and cosmetic applications.

Tips: Consider your primary material focus before choosing a machine. If your business is heavily focused on wood cutting and engraving, a CO2 laser can provide the best efficiency and quality. However, if you intend to process various metals, a fiber laser would be more advantageous due to its speed and precision.

Moreover, it's important to evaluate the power and speed of the laser machine you're considering. Higher wattage typically means faster cutting speeds and thicker material capabilities. Ensure you assess your production volume and choose a machine that aligns with your workload to maximize efficiency. Always seek machines that provide scalable power options, as your business needs may evolve over time.

Key Factors to Consider: Power, Speed, and Precision in Laser Machines

When selecting a laser machine for your business needs, three key factors come to the forefront: power, speed, and precision. Each of these elements plays a significant role in the overall functionality and output quality of the machine.

Power is essential as it determines the material thickness that your laser can effectively cut or engrave. For businesses dealing with thicker materials, a machine with higher wattage is often necessary to achieve clean and efficient results. Conversely, lower-power machines can suffice for lighter tasks, providing a cost-effective solution for small businesses.

Speed, on the other hand, directly affects production efficiency. A faster machine can complete tasks in a shorter time frame, ultimately increasing productivity and allowing businesses to take on more projects. However, speed must be balanced with precision. Cutting or engraving at high speeds can sometimes compromise the quality of the detail in the finished product.

It’s crucial to find a machine that offers a harmonious balance between speed and precision to ensure that the final outcome meets your standards and those of your clients. Investing time in understanding these factors can lead to a more informed decision that aligns with your business goals and requirements.

Evaluating Your Business Needs: Material Types and Production Volume

When selecting the right laser machine for your business, understanding your specific material types and production volume is crucial. According to data from the Laser Institute of America, different laser machines are optimized for various materials such as metals, plastics, and woods. For instance, CO2 lasers excel at cutting and engraving organic materials like wood and acrylic, while fiber lasers are more efficient for metal processing. If your business primarily works with a diverse range of materials, you may need a versatile machine that can adapt to different substrates and application requirements.

Production volume is another key factor in your decision-making process. A report by MarketsandMarkets indicates that businesses with high production demands, such as those in the automotive or aerospace sectors, often benefit from high-powered industrial lasers that can operate continuously with minimal downtime. In contrast, smaller operations or hobbyist-level businesses might find desktop laser cutting systems sufficient for low-volume tasks. Understanding the expected output, whether it involves large-scale production or intricate, low-volume projects, will help you identify a laser machine that not only meets your current needs but also can scale with your business as it grows.

Material Types and Production Volume for Laser Machines

Cost Analysis: Initial Investment vs. Long-term Operational Costs

When considering the purchase of a laser machine for your business, it's essential to conduct a detailed cost analysis that compares the initial investment with long-term operational costs. The initial costs of a laser machine can vary significantly based on its capabilities, features, and complexity. While a higher upfront cost might seem daunting, it often comes with better performance, durability, and efficiency, potentially saving money in the long run.

Tips: When evaluating initial costs, consider not only the purchase price but also installation, training, and any necessary accessories or software. This upfront investment can significantly affect your budget, so be sure to account for all associated expenses.

Long-term operational costs, including maintenance, parts replacement, and energy consumption, can affect your overall profitability. It's crucial to estimate how much you will spend over time on sustaining the equipment to ensure you do not overlook hidden expenses. Additionally, some models may offer better energy efficiency or require less frequent maintenance, which can lead to savings over the machine's lifespan.

Tips: Research the maintenance schedules and the average cost of replacement parts for different models. A machine with lower operational costs can greatly enhance your business's financial health, allowing for reinvestment into other areas.

Maintenance and Support: Ensuring Longevity and Efficiency of Laser Equipment

Proper maintenance and support are vital for ensuring the longevity and efficiency of laser equipment in any business. According to a recent report by the Laser Institute of America, regular maintenance can extend the lifespan of laser machines by up to 30%. This not only helps in reducing unexpected repair costs but also sustains the operational efficiency of the equipment. Adopting a scheduled maintenance program, including daily inspections and regular professional servicing, can prevent small issues from escalating into major failures. Companies that prioritize ongoing maintenance often see an increase in productivity, with reports indicating up to a 25% improvement in workflow efficiency over those that neglect routine care.

Moreover, establishing a reliable support system for laser machinery can further enhance operational efficiency. A survey conducted by the International Society for Optics and Photonics shows that businesses with dedicated support services for their laser equipment experience significantly reduced downtime, averaging only 1.5 hours per month as opposed to 5 hours for those without comprehensive support. Training personnel to understand the complexities of laser operation and maintenance can empower them to troubleshoot minor issues autonomously, preserving equipment functionality and minimizing delays. Therefore, investing in both maintenance and adept support systems is crucial for businesses to maximize the return on their laser technology investments.

How to Choose the Right Laser Machine for Your Business Needs - Maintenance and Support: Ensuring Longevity and Efficiency of Laser Equipment

| Criteria | Details | Importance | Action Steps |

|---|---|---|---|

| Machine Type | CO2, Fiber, or Nd:YAG | High | Evaluate specific processing needs |

| Power Output | Measured in Watts | Medium | Determine thickness and type of materials |

| Maintenance Needs | Routine checks, lens cleaning | High | Create a maintenance schedule |

| Support Options | Technical support, training | Medium | Check provider's support services |

| Software Compatibility | Design software integration | Medium | Confirm software specifications |

| Budget Considerations | Initial cost and ongoing expenses | High | Outline total cost of ownership |

Related Posts

-

Exploring the Future: How Laser Machines Are Revolutionizing Modern Manufacturing Techniques

-

The Ultimate Guide to Choosing the Right Laser Tube for Your Engraving Projects

-

2025's Top 5 Laser Cutting Tables: Unleashing Precision and Innovation

-

Top 10 Benefits of Alpha Laser Technology You Need to Know

-

Top 10 Tips for Perfect Laser Cutting and Bending Techniques You Need to Know

-

Why Alpha Laser Technology is Revolutionizing Industrial Applications in 2023

Machine models and specifications are subject to change without notice.