How to Choose the Right Laser Marking Machine for Your Business Needs?

Choosing the right laser marking machine is crucial for your business. It impacts efficiency, quality, and cost-effectiveness. With various options available, the decision can be overwhelming. You'll need to consider factors such as materials, production speed, and desired outcomes.

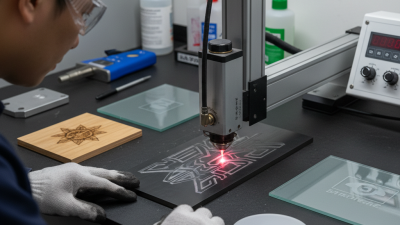

A laser marking machine can engrave, etch, or mark on various surfaces. Think about what you will be marking. Is it metal, plastic, or perhaps wood? Each material requires different laser settings. The size and type of your products also affect your choice. Compact models may suit smaller operations, while industrial solutions are better for large-scale production.

Investing in a laser marking machine is not just about the price tag. It's about long-term returns and reliability. Make sure to research options thoroughly. Price alone shouldn’t be your only concern. After all, a cheaper model may lead to greater costs in the long run. Reflect on your business needs, and you'll find the right machine for you.

Understanding the Basics of Laser Marking Technology

Laser marking technology is an essential tool for many industries today. It offers precision, speed, and durability. According to a recent industry report, the global laser marking market is projected to reach approximately $4 billion by 2026, growing at a CAGR of around 8.5%. This highlights the increasing reliance on laser marking in manufacturing and product identification.

Understanding the basics of laser marking involves recognizing its various techniques. Common methods include fiber, CO2, and UV laser marking. Each type has unique applications. For example, fiber lasers excel in marking metals, while CO2 lasers are best for non-metal materials. Despite advancements, the choice often depends on specific business needs. Some companies struggle to find the right balance between cost and quality, leading to potential inefficiencies.

Moreover, laser marking equipment can be complex. Operators need proper training to maximize its benefits. Misalignment can result in poor marking quality, which affects branding. Industry studies indicate that up to 30% of businesses face challenges with equipment maintenance. This emphasizes the need for ongoing support and strategies to enhance operational efficiency. Investing wisely in laser marking technology can, therefore, yield significant returns when addressing these inherent challenges.

Identifying Your Business Requirements for Marking Solutions

When selecting a laser marking machine, it’s crucial to understand your business needs. Start by identifying what materials you will be marking. Different machines work better with metals, plastics, or glass. Consider your production volume as well. Will you need high-speed marking for mass production? Or is precision your top priority for smaller batches?

Evaluate the marking depth as well. Some applications require shallow marks, while others need deep engraving. Think about the future too. Will your needs change as your business grows? Think about flexibility. A machine that can adapt to new materials or products could save you time and money down the line.

Don’t forget to factor in your budget. Buying the most expensive machine isn’t always the best decision. Affordable options may fulfill your requirements. However, investing in a durable machine with better longevity might be wiser. Consider the maintenance costs as well. Reflect on these details carefully to make a well-informed choice.

Comparing Different Types of Laser Marking Machines

Laser marking machines come in different types, each tailored to specific applications. The key types include fiber, CO2, and YAG lasers.

Fiber lasers are ideal for metal marking. They deliver high precision and speed. Data from industry reports show they have an average lifespan of 100,000 hours. However, they may not be suitable for marking plastics or organic materials.

CO2 lasers excel in marking non-metals. They work well on wood, glass, and acrylic. Many businesses prefer them for their versatility. Yet, their speed may not match that of fiber lasers. One report indicates CO2 lasers operate at 10 to 20% slower speeds than fiber systems. This could impact productivity in high-demand environments.

YAG lasers are often used for deep engraving on metals. These machines provide excellent durability and can handle tough materials. However, the complexity of setup might be a drawback. Operators may need additional training to use YAG systems effectively.

User feedback suggests that while highly efficient, they sometimes require more maintenance and calibration. Thus, a deeper examination of operational resources is essential before choosing the right machine for your business.

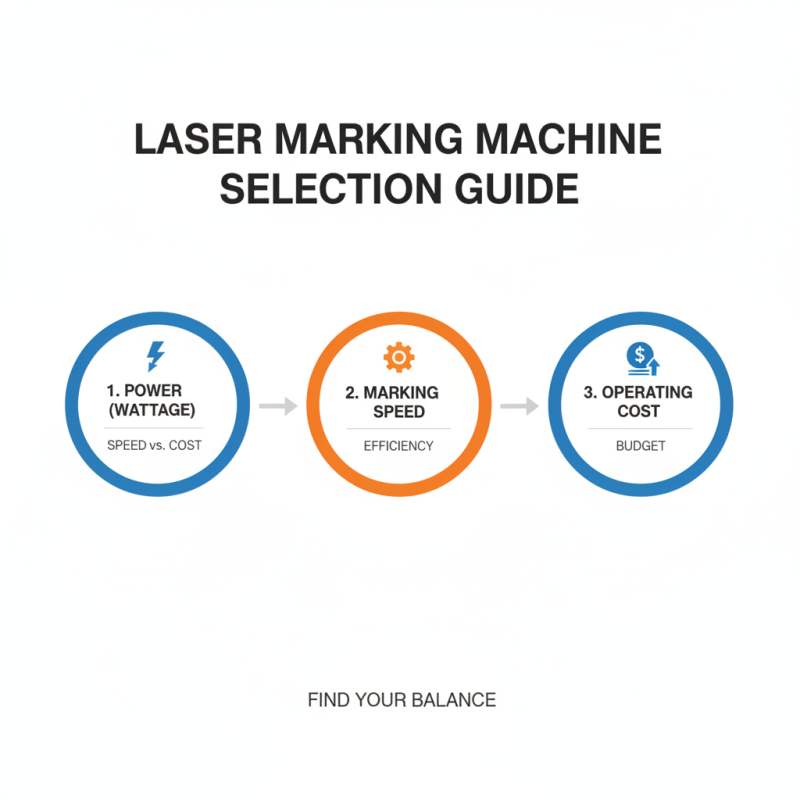

Evaluating Features and Specifications of Laser Markers

When selecting a laser marking machine, several key features deserve attention. Power is crucial. Higher wattage often means faster and more efficient marking. However, more power can also lead to increased costs. Each business needs to find the right balance between speed and expenses.

The type of laser technology is another important aspect. CO2 lasers suit non-metal materials like wood or acrylic. Fiber lasers, on the other hand, work well with metals. Understanding the materials you commonly deal with is essential. Additionally, consider the machine's marking speed and precision. If the machine cannot produce fine details, it may not meet your standards.

Other specifications include the machine's size and its software capabilities. A large machine can accommodate bigger projects but may not fit in all workspaces. Software should be user-friendly to avoid lengthy learning curves. It's also worth reflecting on future needs. Will your business expand? Overlooking scalability can limit your production capabilities later on. Choosing wisely now can save frustrations down the road.

Assessing Budget and Return on Investment for Laser Marking Equipment

When selecting a laser marking machine, budget considerations are crucial. The initial investment can range from $5,000 to over $100,000, depending on the machine's capabilities. A recent industry report states that companies often see a return on investment within two years. However, this timeline varies widely among businesses. Factors such as production volume and application complexity play a significant role.

It's essential to evaluate ongoing costs. Maintenance, supplies, and operational efficiency contribute to overall expenses. Some machines may require more frequent part replacements, impacting long-term budgets. A study found that about 30% of businesses overlook these costs, affecting profitability.

You might face unexpected expenses, too. Upgrading software can improve efficiency but may add costs. Consider hidden costs such as training employees on the new equipment. This could also affect the equipment's usability. Balancing everything is challenging but necessary for informed decisions.

Cost vs Return on Investment for Laser Marking Machines

Related Posts

-

How to Choose the Right Laser Marking Machine for Your Business Needs

-

Laser Marking Machine Tips for Optimal Performance and Usage?

-

Unlocking Precision in Manufacturing with Laser Marking Machines and Their Impact on Production Efficiency

-

How to Choose the Right Laser CNC Machine for Your Projects

-

How to Choose the Best Fiber Laser Engraver for Your Needs?

-

2025 How to Choose the Best Tube Laser Machine for Your Business Needs

Machine models and specifications are subject to change without notice.