How to Choose the Right Fiber Laser Cutting Machine?

Choosing the right fiber laser cutting machine can be a daunting task. With numerous options available, the selection process often raises more questions than answers. Expert Mark Johnson, a well-known figure in the laser technology industry, emphasizes, "Selecting the right machine can transform your production line." His insights underline the importance of careful consideration.

A fiber laser cutting machine's specifications matter greatly. Factors such as power output, speed, and cutting thickness must align with your production needs. Many users overlook these details, leading to suboptimal choices. Understanding materials and project requirements can help you make informed decisions.

Moreover, the support and service offered by manufacturers are essential. A machine can be impressive on paper, but lack of support can hinder performance. Reflecting upon this can prevent regret later. The goal is to invest wisely, ensuring that your fiber laser cutting machine meets both current and future demands.

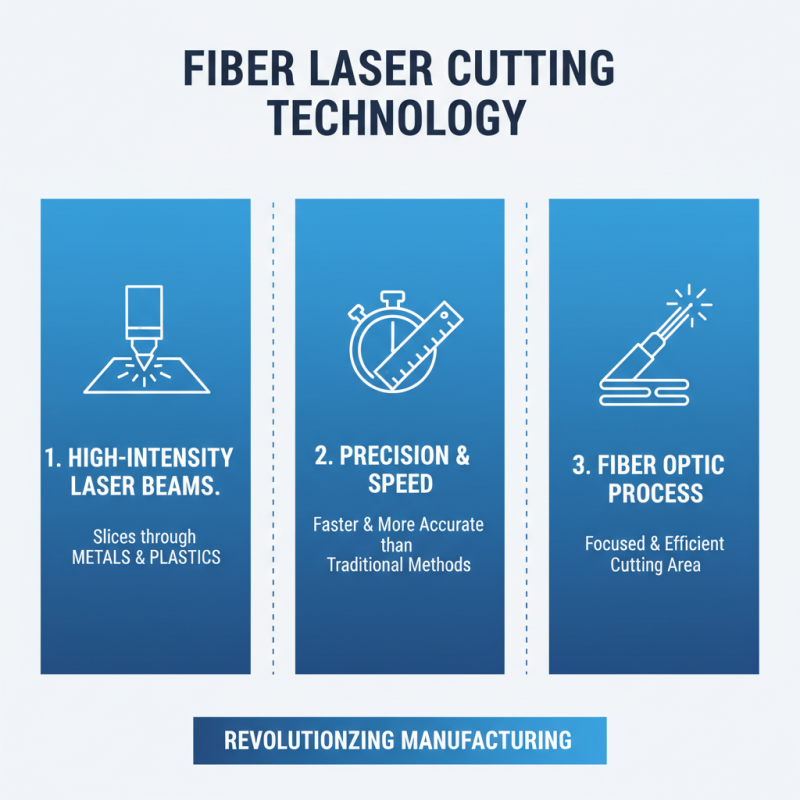

Understanding Fiber Laser Cutting Technology

Fiber laser cutting technology has revolutionized the manufacturing sector. It uses high-intensity laser beams to slice through various materials, such as metals and plastics. This method offers precision and speed, which traditional cutting methods may lack. The beam is generated through a fiber optic process, allowing for a focused and efficient cutting area.

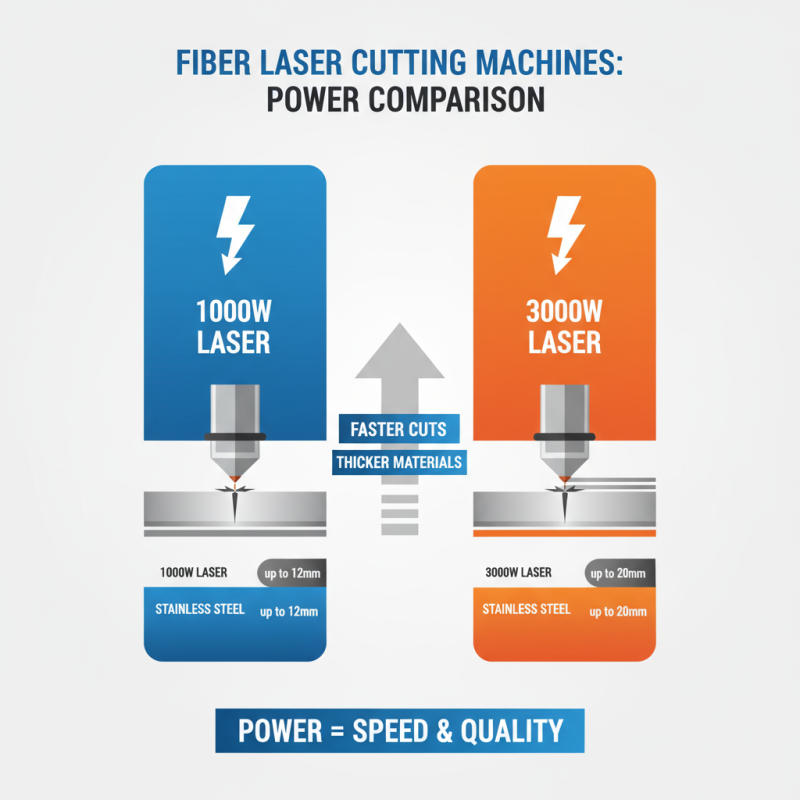

When selecting a fiber laser cutting machine, consider its power and speed. Each model varies in wattage, influencing cutting thickness and speed. High-power machines are beneficial for cutting thicker materials quickly, while lower-powered units are better for thinner sheets. Look closely at the configuration of the machine as well. Some setups may be more complex than expected, requiring additional training or expertise. Compatibility with different materials is another factor to think about.

Maintaining the machine is also crucial. Regular inspection can prevent downtimes that hinder productivity. Consider the cutting bed size as well. A larger bed can accommodate bigger sheets, but it may require more space. This can be a complicated decision. Balancing space and efficiency is not always straightforward in a busy workshop.

Key Factors to Consider When Choosing a Fiber Laser Cutter

Choosing the right fiber laser cutting machine requires careful consideration. One of the key factors is power. Higher wattage allows for faster cutting and deeper penetration. However, it may lead to increased operational costs. Assess your cutting needs based on materials and thickness.

Another important aspect is the cutting speed. Different machines have varied speed capabilities. Generally, a faster machine enhances productivity. But, speed can affect the cut quality. Balance is crucial. Pay attention to the machine's stability as well. A stable cutter ensures accuracy and reduces waste.

Consider the software compatibility too. A user-friendly interface simplifies operation. However, complex software may offer advanced features. Ensure the selected machine aligns with your team's skill level. Lastly, think about maintenance needs. Regular upkeep is essential. It affects the machine's longevity and performance.

Comparing Different Fiber Laser Cutting Machines

When comparing different fiber laser cutting machines, several factors come into play. The power of the laser plays a crucial role. Machines with higher wattage deliver faster cuts and handle thicker materials more efficiently. For instance, a 1000W laser can cut stainless steel up to 12 mm thick, whereas a 3000W machine can cut up to 20 mm. The thickness of the material directly impacts production speed and quality.

Another key element is the type of cutting head. A good cutting head enhances beam quality and stability. This leads to smoother cuts and reduces the need for extensive post-processing. Research indicates that a well-designed cutting head can increase efficiency by up to 30%. However, some users report that it can be difficult to find the right balance between cost and quality.

Software compatibility is often overlooked. The right software can optimize the cutting process, leading to better material utilization. Some systems can save up to 20% in materials by optimizing layouts. Yet, users frequently face challenges with software learning curves. Many operators experience frustration when adapting to new systems, impacting productivity. When choosing, consider your team's skill level and training resources.

Evaluating Cost vs. Performance in Fiber Laser Cutters

Choosing the right fiber laser cutting machine involves a careful balance of cost and performance. You want to maximize productivity while staying within budget. Some machines offer excellent speed but come with a hefty price tag. Others are more affordable but may not deliver the precise cuts you need. The goal is to find the sweet spot between investment and output.

When evaluating options, consider how often you'll use the machine. A lower-cost model might suffice for occasional jobs. If you plan to use the cutter daily, investing in a higher-performance machine may be wise. Think about the materials you’ll work with as well. Some machines handle specific metals better than others. Performance can vary across different thicknesses.

Another factor is the machine's maintenance costs. Cheaper machines might incur more frequent repairs. This can chip away at your savings over time. That said, always consider the potential return on investment. You may end up spending more upfront, but you could earn it back with efficiency gains. Keep an eye on power consumption, as some machines use significantly more electricity. Balancing these factors is crucial for making an informed choice.

How to Choose the Right Fiber Laser Cutting Machine? - Evaluating Cost vs. Performance in Fiber Laser Cutters

| Machine Model | Max Cutting Thickness (mm) | Laser Power (W) | Material Compatibility | Price Range (USD) | Performance Rating (1-10) |

|---|---|---|---|---|---|

| Model A | 10 | 1000 | Mild Steel, Stainless Steel | $15,000 - $20,000 | 8 |

| Model B | 12 | 2000 | Aluminum, Brass | $25,000 - $30,000 | 9 |

| Model C | 8 | 1500 | Stainless Steel, Copper | $18,000 - $22,000 | 7 |

| Model D | 15 | 3000 | Mild Steel, Stainless Steel, Aluminum | $35,000 - $40,000 | 10 |

| Model E | 5 | 500 | Plastic, Acrylic | $8,000 - $12,000 | 6 |

Maintenance and Support for Fiber Laser Cutting Equipment

Maintaining fiber laser cutting machines is crucial for efficiency. Regular maintenance can enhance performance by ensuring precision and reducing downtime. A report by the International Laser Manufacturing Association indicates that routine checks can cut production costs by over 15%. Simple tasks, like lens cleaning and calibration, often get overlooked but are essential for optimal function.

Support for these machines also plays a major role. Many operators assume that hiring skilled technicians is a costly option. In reality, having expert support can prevent major breakdowns that lead to higher costs. A study published in the Journal of Manufacturing Technologies found that over 30% of laser cutting downtime could be avoided with proper support systems in place.

Investing in training for staff is another overlooked area. Well-trained users are less likely to misuse equipment. The skills gap in this sector can lead to increased errors. Regular training sessions can bridge this gap. The importance of maintaining and supporting fiber laser equipment cannot be stressed enough. Without it, the risk of failure rises significantly, affecting both quality and output.

Maintenance Frequency for Fiber Laser Cutting Machines

This bar chart illustrates the recommended maintenance frequency for fiber laser cutting machines, measured in hours across different time frames. Regular maintenance is crucial to ensure optimal performance and longevity of the equipment.

Related Posts

-

Top 5 Reasons to Invest in a CNC Laser Cutter for Your Business

-

Top 10 CNC Laser Cutting Machines for Precision Fabrication in 2023

-

What is a CNC Laser Cutter? Benefits, Uses, and How It Works Explained

-

What is a Laser Cutting Machine and How Does it Work for Your Projects

-

What is CNC Fiber Laser Cutting Machine and How Does It Work

-

Exploring the Future: How Laser Machines Are Revolutionizing Modern Manufacturing Techniques

Machine models and specifications are subject to change without notice.