Top 10 CNC Cutting Techniques for Precision and Efficiency in Manufacturing

In the ever-evolving landscape of manufacturing, precision and efficiency stand as the cornerstones of success, with CNC cutting technologies leading the charge. John Smith, a renowned expert in CNC cutting techniques, has stated, "Masters of CNC cutting understand the delicate balance between precision and speed, ultimately driving innovation and productivity." As manufacturers around the globe strive for competitive advantage, understanding the various CNC cutting methods becomes paramount.

This article explores the top ten CNC cutting techniques that not only enhance precision but also significantly improve operational efficiency. From laser cutting to waterjet cutting, each method brings unique advantages that can be tailored to specific manufacturing needs. As industry leaders leverage these techniques, the interplay of technology and expertise becomes clear, revealing how the right approach to CNC cutting can revolutionize production processes and foster growth in an increasingly competitive marketplace. Through this exploration, readers will gain valuable insights into the tools and strategies that are shaping the future of manufacturing.

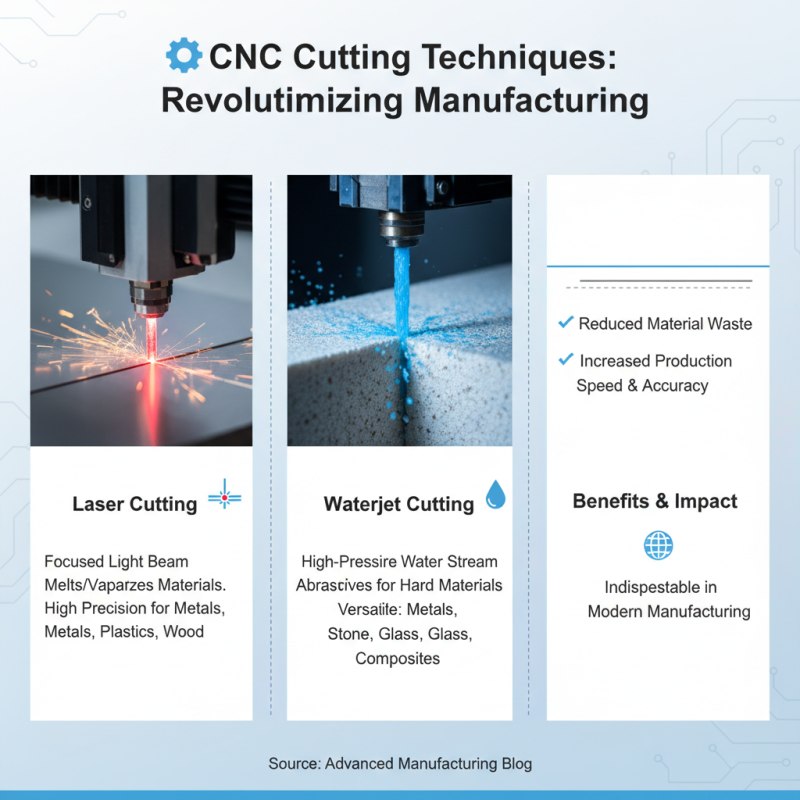

Overview of CNC Cutting Techniques in Modern Manufacturing

CNC cutting techniques have revolutionized modern manufacturing by providing precise and efficient methods for shaping materials. These advanced techniques utilize computer numerical control systems to automate cutting processes, enabling manufacturers to achieve high levels of accuracy and repeatability. From laser cutting, which uses focused light beams to melt or vaporize materials, to waterjet cutting, which employs high-pressured water streams, CNC cutting methods cater to various materials and complexities. These techniques reduce material waste and improve production speed, making them indispensable in today's competitive market.

In addition to laser and waterjet cutting, technologies like plasma cutting and CNC machining have also emerged as vital components of modern manufacturing. Plasma cutting is ideal for conductive metals, as it utilizes an ionized gas to create a high-temperature plasma arc, while CNC machining encompasses various processes such as milling and turning for more intricate designs. These methods allow manufacturers to tailor their production processes to specific project requirements, enhancing overall efficiency. The integration of CNC cutting techniques into manufacturing workflows exemplifies the industry's shift towards automation and precision, ultimately driving innovation and productivity in various sectors.

Key Factors Influencing Precision in CNC Cutting Processes

Precision in CNC cutting processes is vital for achieving high-quality manufacturing outcomes. Several key factors influence this precision, beginning with the quality of the cutting tools themselves.

High-quality, well-maintained cutting tools not only ensure cleaner cuts but also minimize wear and tear, which can lead to inaccuracies over time. Additionally, selecting the appropriate tool geometry based on the material being cut plays a significant role in achieving precise results. Factors such as tool sharpness, shape, and width must align with the specific characteristics of the material to optimize performance.

Another critical aspect is the calibration and setup of the CNC machine. Proper alignment and zeroing of the machine ensure that the cutting head operates with a high degree of accuracy. Regular maintenance checks and recalibrations are necessary to maintain the machine's performance, reducing the risk of drift or misalignment.

Furthermore, the programming of the CNC system itself—including feed rates, cutting speeds, and depth of cuts—must be meticulously calculated to accommodate the variable attributes of different materials. By carefully managing these factors, manufacturers can significantly enhance precision in their CNC cutting processes.

Comparative Analysis of Different CNC Cutting Techniques

When it comes to CNC cutting techniques, a comparative analysis reveals a spectrum of methods that cater to various manufacturing needs. Techniques like laser cutting, waterjet cutting, and plasma cutting each possess distinct advantages and limitations. Laser cutting excels in precision and speed, making it an ideal choice for intricate designs and thin materials. In contrast, waterjet cutting offers versatility, as it can handle thicker materials without introducing thermal stress, thus preserving the integrity of the workpiece. Plasma cutting, while suitable for thicker metals, may lag in precision, but it's favored for its speed and cost-effectiveness in bulk operations.

Tips for selecting the right CNC cutting technique include evaluating the material type and thickness, as these factors significantly influence the choice of method. For example, if your project requires extreme precision in a delicate material, laser cutting might be your best bet. On the other hand, for large-scale operations involving thick metal sheets, plasma cutting could enhance efficiency while reducing costs. Additionally, consider the post-processing requirements, as certain techniques may require more finishing work, which can impact overall productivity.

Ultimately, understanding the nuances of each CNC cutting technique allows manufacturers to make informed decisions that enhance both precision and efficiency in their production processes. Investing time in this comparative analysis not only aids in immediate project success but also fosters long-term improvements in manufacturing capabilities.

Top 10 CNC Cutting Techniques: Precision and Efficiency

Applications of CNC Cutting Techniques Across Various Industries

CNC cutting techniques have revolutionized various industries by offering unparalleled precision and efficiency. In the aerospace sector, these techniques are employed to manufacture intricate components that must meet stringent safety standards. By utilizing advanced CNC routers and lasers, manufacturers can create lightweight yet durable parts with a high degree of accuracy, significantly reducing the time and cost associated with traditional machining methods.

In the automotive industry, CNC cutting plays a crucial role in enhancing production processes. From complex engine components to body parts, CNC machines ensure repeatability and precision during the manufacturing process. This leads to improved performance and safety in vehicles while allowing for customization to meet diverse consumer demands. Furthermore, industries like woodworking and electronics benefit from CNC technologies, enabling them to produce intricate designs and components that are essential for modern applications, demonstrating the versatility and adaptability of CNC cutting techniques across various fields.

Future Trends in CNC Cutting Technology and Efficiency Improvements

As the manufacturing landscape continues to evolve, the future of CNC cutting technology is poised for significant advancements that promise to enhance both precision and efficiency. One of the promising trends is the integration of artificial intelligence (AI) and machine learning into CNC systems. These technologies can analyze vast amounts of data in real-time, optimizing cutting paths, reducing idle times, and predicting maintenance needs before issues arise. This proactive approach not only streamlines production but also ensures that machines operate at peak performance levels, thus reducing waste and maximizing output.

Another trend gaining traction is the adoption of multi-axis CNC cutting tools. These advanced machines expand the range of complex shapes and designs that can be manufactured with high precision. With the ability to cut from multiple angles and orientations, manufacturers can achieve intricate geometries that were previously difficult or impossible to replicate. Coupled with the ongoing development of innovative cutting materials and techniques, such as laser and plasma cutting, the capability to produce high-quality, detailed components efficiently will continue to shape the future of CNC cutting technology. As these enhancements come to the forefront, they will fundamentally transform not just the processes used in manufacturing but also the expectations for speed and accuracy in production.

Related Posts

-

How CNC Cutting Technology Is Revolutionizing Manufacturing: Insights and Trends for 2024

-

Top 10 CNC Cutting Techniques for Precision and Efficiency in Manufacturing

-

Top 10 Tips for Perfect Laser Cutting and Bending Techniques You Need to Know

-

How to Choose the Best CNC Cutting Machine for Your Projects

-

What is a CNC Laser Cutter? Benefits, Uses, and How It Works Explained

-

Top 5 Reasons to Choose Tube Laser Cutting for Your Next Project

Machine models and specifications are subject to change without notice.