What is CNC Fiber Laser Cutting Machine and How Does It Work

The CNC fiber laser cutting machine represents a significant advancement in the manufacturing sector. According to a recent market report, the global fiber laser market is projected to reach $5 billion by 2025. This machine utilizes high-intensity laser beams to cut materials with precision and efficiency. As industries seek ways to enhance productivity, CNC fiber laser cutting technology has proven invaluable.

This technology offers several advantages over traditional cutting methods. It is faster, more accurate, and reduces material waste. Additionally, the CNC fiber laser cutting machine operates with lower energy consumption, aligning with modern sustainability goals. However, there are challenges as well. Operators need training to optimize performance. Misalignments can occur if machines are not calibrated correctly.

In an ever-evolving manufacturing landscape, it is clear that the CNC fiber laser cutting machine is a game-changer. Its adoption can vastly improve operational capabilities, but businesses must continuously assess their processes for improvements. The journey toward optimal efficiency is ongoing and requires reflection and adaptation.

What is a CNC Fiber Laser Cutting Machine?

A CNC fiber laser cutting machine is an advanced tool for precision cutting. It uses fiber-optic technology to generate a high-powered laser beam. This beam can melt or burn through a variety of materials. Metals, plastics, and wood are common materials used in this process. The CNC component means it's controlled by a computer program. This allows for intricate designs and repeatable results with high accuracy.

One tip when using these machines is to ensure proper material setup. Misalignment can lead to wasted material and time. Adjust settings according to material types for better results. Also, keep the lens clean. A dirty lens can diminish cutting quality.

Safety is essential with fiber laser machines. Protective gear should always be worn. The workspace should be clear of unnecessary items to avoid accidents. Regular maintenance is vital to keep the machine operating efficiently. Even minor issues can lead to significant downtime if not addressed promptly. Consider keeping a checklist for regular checks.

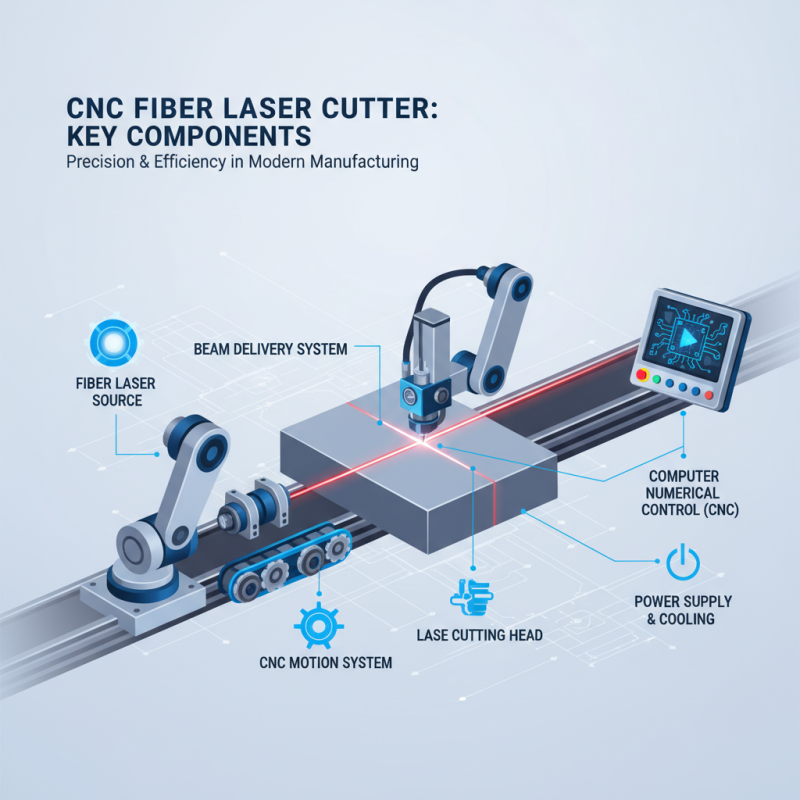

Key Components of CNC Fiber Laser Cutting Machines

CNC fiber laser cutting machines are sophisticated tools used in various industries. The key components of these machines make their operation efficient and precise. The fiber laser source is crucial; it generates high-intensity light, which is fundamental for cutting operations. This source uses advanced technology to produce beams that can cut through various materials with ease.

Another important component is the CNC controller. This device interprets digital designs and translates them into machine movements. It ensures that the laser head moves accurately along predetermined paths. However, controlling complex curves can sometimes lead to minor inaccuracies. Operators must regularly check and calibrate settings to maintain precision.

The cutting head, equipped with focusing lenses, plays a vital role. It concentrates the laser beam onto the material, allowing quick and clean cuts. Different lenses can produce varying spot sizes, influencing the quality and speed of the cut. Notably, achieving optimal focus can be tricky at times. Operators need to be vigilant about this aspect to avoid wasting materials or creating rough edges.

Principles of Operation: How CNC Fiber Lasers Cut Materials

CNC fiber laser cutting machines operate based on precise and controlled laser technology. The laser produces an intense beam of light, focused through a fiber optic cable. This light energy is used to cut through materials like metal, wood, and plastic. The machine's computer numerically controls the laser, guiding it along programmed paths for accuracy.

When the laser hits the material, it heats it to extreme temperatures. This results in a rapid melting or vaporization process, allowing for clean and sharp cuts. The CNC system ensures that the laser moves steadily, maintaining a consistent speed. It’s this control that differentiates fiber lasers from traditional cutting methods.

Tips: Regular maintenance of the laser and optics improves efficiency. Make sure to calibrate the machine often. Even minor changes can lead to significant cutting errors. Always test the settings with scrap material first. It’s better to waste a small piece than to ruin an entire project. Remember, precision is key in CNC operations, but don’t fear making adjustments as you learn.

Advantages of Using CNC Fiber Laser Technology in Manufacturing

CNC fiber laser cutting technology has transformed manufacturing. It offers unmatched precision in cutting various materials. This technology uses focused laser beams to slice through metal, wood, and plastics. The result is clean and accurate edges, significantly reducing waste.

One significant advantage is speed. Fiber lasers operate faster than traditional cutting methods. This efficiency can lead to higher productivity. Companies can meet tight deadlines and handle larger orders effectively. However, not all materials yield the same results.

Tip: Always test your materials before large-scale production. Some metals may require different settings. Adjustments can enhance quality and performance.

Another benefit is lower operational costs. CNC fiber lasers require less energy compared to other cutting methods. They also need minimal maintenance. This can save manufacturers on energy bills and upkeep. However, the initial investment in technology can be high.

Tip: Consider the long-term savings when evaluating costs. Investing wisely can lead to substantial rewards over time. Balancing initial expenses with potential gains is crucial for growth.

What is CNC Fiber Laser Cutting Machine and How Does It Work - Advantages of Using CNC Fiber Laser Technology in Manufacturing

| Feature | Description |

|---|---|

| Cutting Precision | High precision cutting with tolerances of ±0.01 mm. |

| Speed | Fast cutting speeds of up to 30 meters per minute. |

| Material Compatibility | Compatible with metal, wood, acrylic, and other materials. |

| Operating Costs | Lower operating costs due to reduced energy consumption. |

| Maintenance | Minimal maintenance required compared to traditional methods. |

| Safety Features | Equipped with safety sensors and enclosures for operator safety. |

| Software Integration | Compatible with various CAD/CAM software for design processing. |

Industry Applications and Market Trends of CNC Fiber Laser Cutters

CNC fiber laser cutting machines have gained popularity across various industries. Their precision and efficiency are appealing. Many manufacturers utilize these machines for cutting metal sheets, pipes, and other materials. The automotive and aerospace sectors are among the largest users. Their need for precise cuts is paramount for safety and performance.

Market trends show a growing demand for CNC fiber laser cutters. Smaller companies are adopting this technology, thanks to decreasing costs. This opens up opportunities in diverse sectors. Applications range from art to architecture. Many industries appreciate the flexibility of fiber lasers. However, technical training is often lacking in smaller firms. This can lead to inefficiencies in operation.

Tips: Before investing, evaluate your specific needs. Research potential suppliers and options available. Understand the maintenance requirements. A good maintenance plan is essential for longevity. Additionally, encourage continuous training in your team. This will improve overall efficiency and output quality. Keep in mind that not all jobs are suited for laser cutting. Consider the material type and thickness before proceeding.

CNC Fiber Laser Cutting Machine Market Trends

Related Posts

-

10 Best Laser Cutting Tables for Precision and Efficiency in 2023

-

What is a CNC Laser Cutter and How Does it Work for Your Projects

-

Top 10 CNC Fiber Laser Cutting Machines for Precision and Efficiency

-

Top 10 Tips for Perfect Laser Cutting and Bending Techniques You Need to Know

-

What is a Laser Cutting Machine and How Does it Work for Your Projects

-

2025 How to Choose the Best Tube Laser Machine for Your Business Needs

Machine models and specifications are subject to change without notice.