What is a CNC Laser Cutter? Benefits, Uses, and How It Works Explained

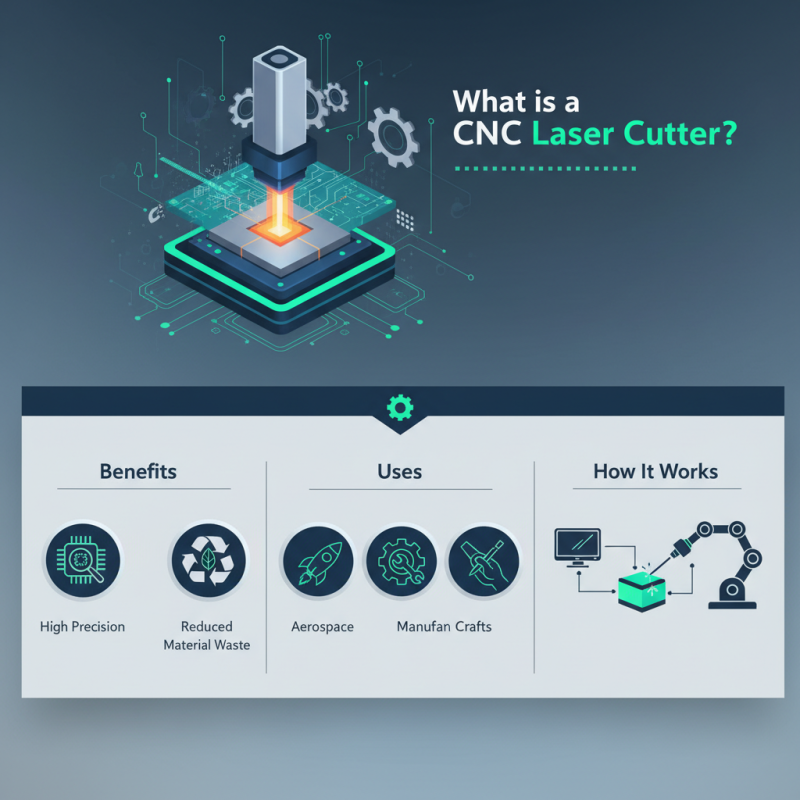

In the realm of manufacturing and design, precision and efficiency are paramount. A CNC laser cutter stands out as a remarkable tool that combines advanced technology with cutting-edge capabilities. This innovative machine utilizes a computer-controlled laser to perform intricate cutting, engraving, and marking on various materials, making it an essential asset in numerous industries, from aerospace to artisan crafts.

Understanding what a CNC laser cutter is and how it operates is crucial for anyone looking to enhance their manufacturing processes or explore new creative avenues. This introduction will delve into the benefits of using a CNC laser cutter, such as its ability to achieve high precision and reduce material waste, along with its versatile applications across different fields. By exploring these aspects, we can appreciate the significance of CNC laser cutting technology in today's fast-paced production environment and its growing role in shaping the future of fabrication.

What is a CNC Laser Cutter?

A CNC laser cutter is a sophisticated tool that utilizes a high-powered laser beam to cut or engrave various materials with exceptional precision. CNC stands for Computer Numerical Control, meaning the machine operates automatically through programmed commands from a computer. This technology allows the cutter to execute intricate designs that would be challenging to achieve with traditional cutting methods. It is widely used in industries such as manufacturing, woodworking, metalworking, and textiles due to its versatility and efficiency.

The working principle of a CNC laser cutter involves directing a concentrated beam of light that produces intense heat. This heat melts, burns, or vaporizes the material, allowing for clean cuts and detailed engravings. The process is highly customizable, enabling operators to adjust parameters such as speed, power, and frequency to accommodate different materials like wood, acrylic, metal, and glass. The precision of CNC laser cutting not only minimizes waste but also enhances the overall speed of production, making it an invaluable tool for businesses aiming to streamline their operations and improve their product quality.

Manufacturing Process Comparison: CNC Laser Cutting vs Traditional Cutting Methods

Key Components of CNC Laser Cutting Machines

CNC laser cutting machines are composed of several key components that work together to execute precise cutting operations. At the heart of the system is the laser source, which generates a focused beam of light that can cut through various materials with high accuracy. This is complemented by a motion control system that moves the cutting head along various axes, enabling intricate designs to be achieved efficiently. The CNC (Computer Numerical Control) software translates design files into instructions for the machine, ensuring that every cut is executed as intended.

Another essential component is the cutting table, which supports the material being cut and often includes features to manage fume extraction and cooling. Often overlooked, the lens and mirror system is vital for focusing the laser beam to achieve the desired intensity and precision. Proper maintenance of these components is crucial for optimal performance and longevity.

**Tips:** When using a CNC laser cutter, always ensure that the material is securely fastened to the cutting table to prevent any movement during the process, which could lead to inaccuracies. Additionally, routine inspections of the laser optics can prevent costly misalignments and enhance the efficiency of your cuts. Regularly updating your toolpaths in the CNC software can also lead to improved cutting speeds and material utilization.

What is a CNC Laser Cutter? Benefits, Uses, and How It Works Explained - Key Components of CNC Laser Cutting Machines

| Dimension | Description |

|---|---|

| Type of Laser | CO2 Laser, Fiber Laser, Nd:YAG Laser |

| Cutting Thickness | Up to 25 mm for metals; 20 mm for acrylics |

| Material Compatibility | Metals, Plastics, Wood, Fabric, Leather, Glass |

| Precision | Up to 0.01 mm |

| Speed of Cutting | Up to 120 m/min |

| Advantages | High precision, Fast processing, Minimal material waste |

| Typical Applications | Sign making, Industrial part production, Jewelry cutting, Artistic designs |

| Key Components | Laser source, Focusing lens, CNC motion system, Control computer |

Benefits of Using CNC Laser Cutters in Various Industries

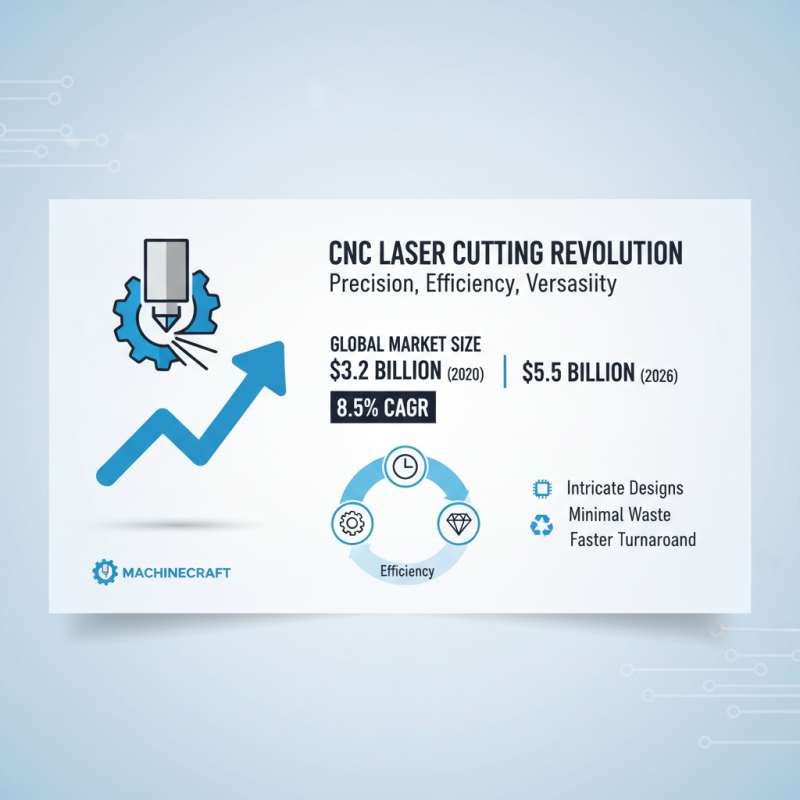

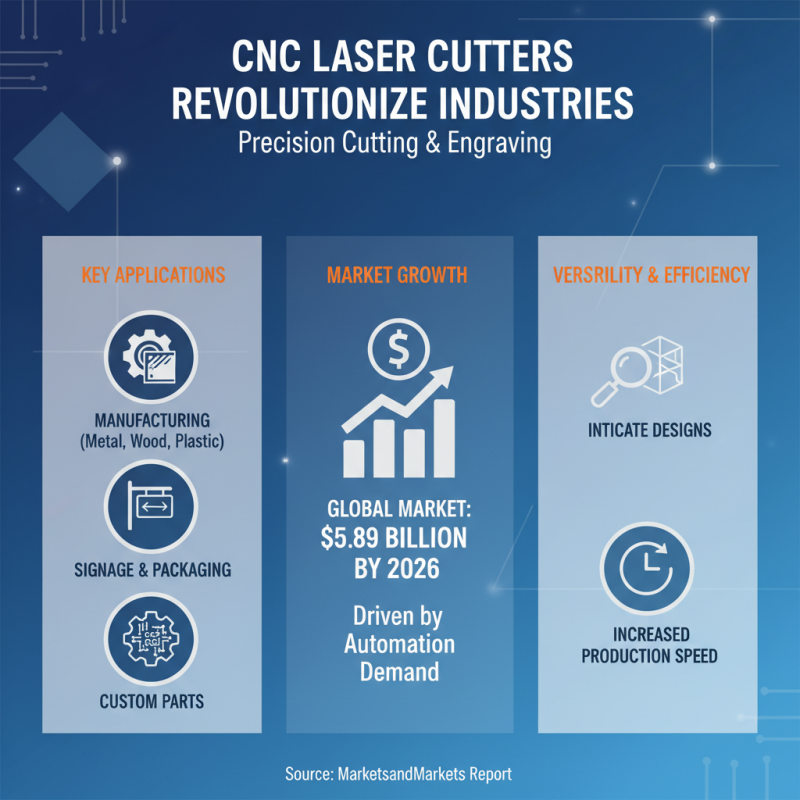

CNC laser cutters have revolutionized manufacturing processes across various industries, offering precision, efficiency, and versatility that traditional methods cannot match. According to a report from MarketsandMarkets, the global laser cutting market size was valued at $3.2 billion in 2020 and is projected to reach $5.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 8.5%. This escalating demand is driven by the laser cutter's ability to process intricate designs with minimal material waste and faster turnaround times.

In the automotive industry, for instance, CNC laser cutters are utilized for cutting, engraving, and etching metal and plastics, enhancing both component design and production efficiency. Lasers can achieve tolerances as tight as 0.1mm, which significantly improves the fit and function of parts. In the aerospace sector, where weight reduction is crucial, the precision cutting capabilities of CNC laser technology enable the creation of lightweight components without compromising structural integrity. Furthermore, in the fashion and textile industries, designers leverage CNC laser cutting for intricate patterns and designs, allowing for greater creativity and reducing lead times by automating cutting processes.

The benefits of CNC laser cutters extend to the healthcare sector as well, where custom medical devices and implants can be produced with exceptional accuracy and biocompatibility. A study published in the Journal of Laser Applications highlighted that teams employing CNC laser cutting in medical device manufacturing reported up to a 30% reduction in production time and significant cost savings, underscoring the technology's transformative impact across diverse applications.

Common Applications and Uses of CNC Laser Cutters

CNC laser cutters have revolutionized various industries by providing precise cutting and engraving capabilities. One of the most common applications of CNC laser cutters is in the manufacturing sector, particularly for the processing of metal, wood, and plastic. According to a report by MarketsandMarkets, the global laser cutting market is expected to reach $5.89 billion by 2026, driven by the increasing demand for automation in manufacturing processes. These machines are also widely used in creating intricate designs for signage, packaging, and custom parts, showcasing their versatility and efficiency.

In the arts and crafts realm, CNC laser cutters enable artists and designers to push the boundaries of creativity. From personalized gifts to intricate artworks, the ability to cut and engrave with high precision allows for innovative designs that were previously difficult to achieve. Additionally, the fashion industry utilizes CNC laser cutting for detailed fabric work, allowing for unique patterns and textures that enhance garment aesthetics.

Tips: When considering a CNC laser cutter for your business, evaluate the materials you will work with and the thickness of those materials, as different lasers cater to various applications. It's also essential to factor in the machine's speed and precision, which can significantly impact production time and quality. Investing in proper training for your staff can also maximize the benefits of this technology, enhancing productivity and creativity in your projects.

The Working Principle: How CNC Laser Cutting Operates

CNC laser cutting operates through a sophisticated process that leverages computer numerical control to guide a laser beam with remarkable precision. At its core, the system utilizes a highly focused laser emitted from a resonator, which generates a concentrated energy beam capable of cutting through various materials including metal, wood, plastic, and glass. The process starts with a digital design that is translated into machine-readable code, allowing the CNC machine to interpret and execute the cutting path accordingly. According to a report by the Laser Institute of America, this method can achieve a cutting tolerance of ±0.005 inches, making it ideal for intricate designs and tight specifications.

One of the key advantages of CNC laser cutting lies in its speed and efficiency. With cutting speeds often exceeding 100 inches per minute, laser cutters substantially reduce production times compared to traditional methods. Furthermore, their ability to cut complex geometries without the need for additional tooling minimizes material wastage, aligning with sustainable manufacturing practices. A study from IBISWorld highlights that advancements in laser technology have led to increased adoption across various industries, predicting a continued growth of approximately 5% over the next five years.

Tips: When using CNC laser cutters, always ensure that the material being processed is suitable for laser cutting to avoid hazardous fumes and combustion. Regular maintenance of the equipment, including lens cleaning and alignment checks, is essential for optimal performance and longevity of the machine. Additionally, investing in software that facilitates accurate design conversions can streamline the workflow and enhance productivity.

Related Posts

-

Top 5 Reasons to Invest in a CNC Laser Cutter for Your Business

-

What is a CNC Laser Cutter and How Does it Work for Your Projects

-

2025's Top 5 Laser Cutting Tables: Unleashing Precision and Innovation

-

Top 10 CNC Fiber Laser Cutting Machines for Precision and Efficiency

-

How to Choose the Right Laser CNC Machine for Your Projects

-

2025 How to Choose the Best Tube Laser Machine for Your Business Needs

Machine models and specifications are subject to change without notice.