Why Pipe Laser Cutting is the Future of Precision Manufacturing?

In the rapidly evolving landscape of precision manufacturing, pipe laser cutting is capturing unprecedented attention. According to a recent report by Research and Markets, the global laser cutting market is projected to reach $6.4 billion by 2025. This growth highlights the increasing adoption of advanced cutting technologies. Experts in the field are reassessing traditional methods, as laser cutting offers higher efficiency and improved accuracy.

John Smith, a leading authority in laser technology, states, "Pipe laser cutting represents a monumental shift in how we approach fabrication." His insights underline the transformative potential of this process. Manufacturers are seeing enhanced productivity, reduced waste, and lower operational costs. However, challenges remain. Transitioning to new technologies often requires significant investment and training. Companies must reflect on their existing practices to fully utilize these advancements.

As industries continue to demand precision, the question remains: Will all manufacturers adapt swiftly enough to harness the benefits of pipe laser cutting? Embracing change is essential, but not without its hurdles.

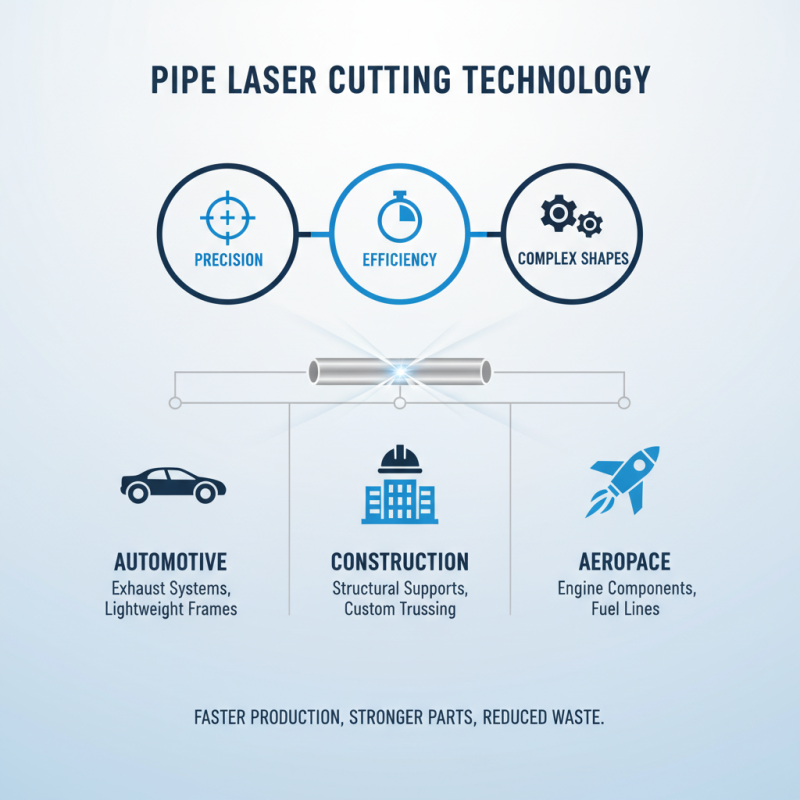

Advantages of Pipe Laser Cutting in Modern Manufacturing Processes

Pipe laser cutting has become a vital method in modern manufacturing. This technique offers unparalleled precision and efficiency. It uses focused laser beams to cut through metal pipes, creating clean, accurate edges. Manufacturers benefit from reduced waste and lower production costs. The adaptability of laser cutting allows for various pipe sizes and materials.

One notable advantage is speed. Pipe laser cutting can significantly reduce production time. Traditional methods may take longer, leading to delays. However, laser technology efficiently cuts complex shapes without losing precision. This opens new possibilities for design innovation. Yet, some challenges remain. Initial setup costs for laser cutting equipment can be high. Additionally, operators require specialized training to handle these advanced machines.

The level of detail achievable with pipe laser cutting is remarkable. Intricate designs can be produced with minimal effort. However, the need for constant maintenance is crucial. Ignoring this aspect may lead to reduced accuracy over time. Balancing quality and cost is always a consideration in the manufacturing process. Pipe laser cutting represents a forward-thinking approach. While it’s transformative, it still prompts reflection on evolving best practices.

Technological Innovations Driving Pipe Laser Cutting Forward

Laser cutting technology has transformed pipe manufacturing by offering precision and efficiency. Recent reports indicate that the pipe laser cutting market is expected to grow at a CAGR of 8.3% through 2027. This growth is driven by the demand for high-quality cuts and the ability to handle diverse materials. As industries push for more streamlined processes, laser cutting provides a solution for producing intricate designs.

Technological innovations play a crucial role in advancing pipe laser cutting. New systems integrate automation and real-time monitoring. These features improve accuracy and reduce waste. According to a study by the Manufacturing Technology Association, up to 30% of materials can be spared with precise laser techniques. However, there are challenges. High initial costs and the need for skilled operators can deter some companies. Many are hesitant about the return on investment.

Custom solutions are emerging in the sector. Manufacturers adapt laser cutting to serve niche markets while enhancing manufacturing capabilities. This flexibility allows small to medium enterprises to compete with giants. Future trends suggest a shift towards hybrid technologies, combining laser and traditional cutting methods. An exciting prospect but not without its complexities. Companies must continuously assess their operations to fully leverage these innovations.

Applications of Pipe Laser Cutting Across Various Industries

Pipe laser cutting technology has transformed various industries in recent years. Its precision and efficiency are unrivaled. This method is widely used in automotive manufacturing, construction, and aerospace. For instance, in the automotive sector, companies utilize laser cutting for creating complex pipe shapes used in exhaust systems. These parts fit perfectly, resulting in better performance and reduced emissions.

In the energy sector, pipe laser cutting plays a vital role. It aids in manufacturing pipelines used in oil and gas. The precision of laser cutting minimizes waste, which is crucial in this industry where margins are tight. In construction, builders appreciate the technology for its ability to produce intricate designs. This capability allows for unique architectural features that set projects apart.

However, not all companies have fully adopted this technology. Some still rely on traditional methods, leading to longer production times and increased costs. This presents a challenge. Companies must weigh the benefits against the initial investment. Transitioning to laser cutting may require training and adaptation. Yet, those willing to embrace this technology can significantly enhance their production capabilities.

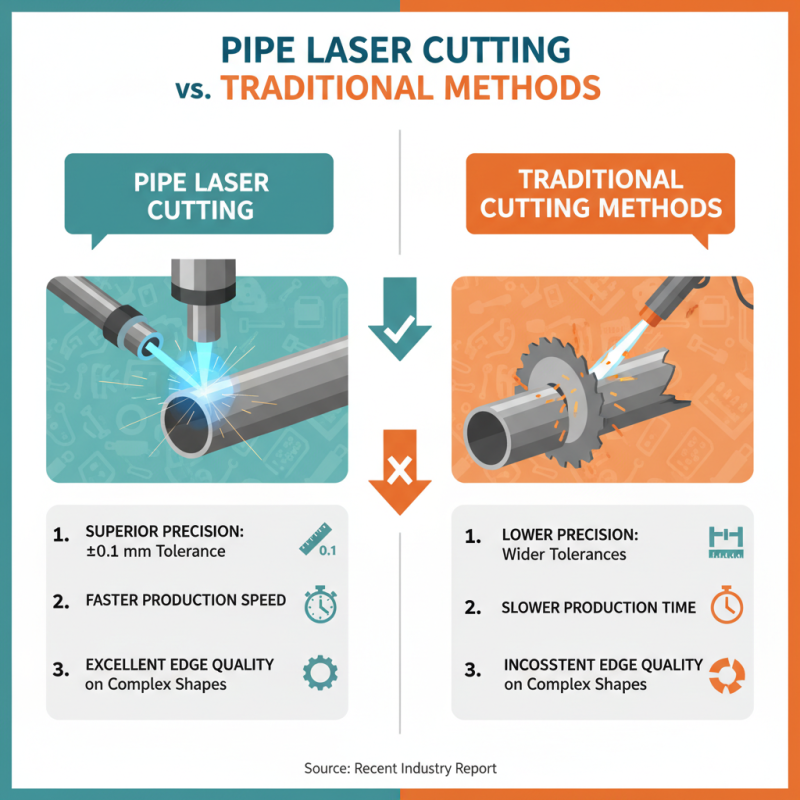

Comparative Analysis: Pipe Laser Cutting vs. Traditional Cutting Methods

Pipe laser cutting stands out when compared to traditional cutting methods. It offers superior precision and speed. According to a recent industry report, laser cutting can achieve tolerances as tight as ±0.1 mm. This level of accuracy is often unattainable with conventional cutting tools. Traditional methods struggle to maintain consistent edge quality on intricate shapes.

In terms of operational efficiency, laser cutting reduces waste. A study revealed that laser systems can minimize material waste by up to 30%. This contrasts sharply with mechanical cutting processes, which can leave significant scrap. Additionally, laser systems often require less operational downtime. This is a notable advantage when scheduling production.

Despite its benefits, challenges exist. Initial setup costs for laser cutting equipment can be steep. Many businesses hesitate to invest in new technology without clear long-term benefits. Operator training is also essential, as mishandling can lead to costly mistakes. Balancing these factors can be tough. Transitioning from old methods to laser cutting needs careful planning. As manufacturers weigh these considerations, the future of precision manufacturing becomes increasingly focused on laser technology.

Future Trends and Developments in Pipe Laser Cutting Technology

The evolution of pipe laser cutting technology is shaping the future of precision manufacturing. Recent advancements are driving efficiency and accuracy in production processes. This shift brings new capabilities, enabling businesses to achieve intricate designs with ease. The use of high-powered lasers ensures clean cuts and reduces waste. Manufacturers can now handle complex geometries that were once challenging.

Future developments will focus on automation and integration with AI. As machines become smarter, they will optimize cutting paths and reduce operational downtime. Innovations in software are also allowing for better design simulations, improving workflow and accuracy. These changes promise a significant increase in productivity. However, the technology requires continuous learning and adaptation from operators.

It's worth noting that while advancements are impressive, they may come with a learning curve. Some workers might find it challenging to adjust to new systems. This transition could lead to initial mistakes and inefficiencies. Embracing these challenges is essential for progress in the industry. The future appears bright, but careful navigation is needed to fully realize the benefits of this technology.

Why Pipe Laser Cutting is the Future of Precision Manufacturing? - Future Trends and Developments in Pipe Laser Cutting Technology

| Application | Industry | Precision Level | Material Types | Future Potential |

|---|---|---|---|---|

| Tubes and Pipes Cutting | Manufacturing | ±0.1 mm | Steel, Aluminum, Copper | High demand due to automation |

| Complex Shapes Cutting | Automotive | ±0.05 mm | Alloys, Plastic-coated Materials | Innovative designs for lightweight structures |

| High-speed Cutting | Aerospace | ±0.025 mm | Titanium, Carbon Fiber | Growing use in aircraft components |

| Automated Production Lines | Construction | ±0.1 mm | PVC, Composites | Potential for smart manufacturing integration |

Related Posts

-

10 Best Laser Cutting Tables for Precision and Efficiency in 2023

-

How to Choose the Right Fiber Laser Cutting Machine?

-

Top 5 Reasons to Choose Tube Laser Cutting for Your Next Project

-

What is a Laser Cutting Machine and How Does it Work for Your Projects

-

What is CNC Fiber Laser Cutting Machine and How Does It Work

-

2025 How to Choose the Best Tube Laser Machine for Your Business Needs

Machine models and specifications are subject to change without notice.