Top 10 CNC Laser Machines You Must Know About?

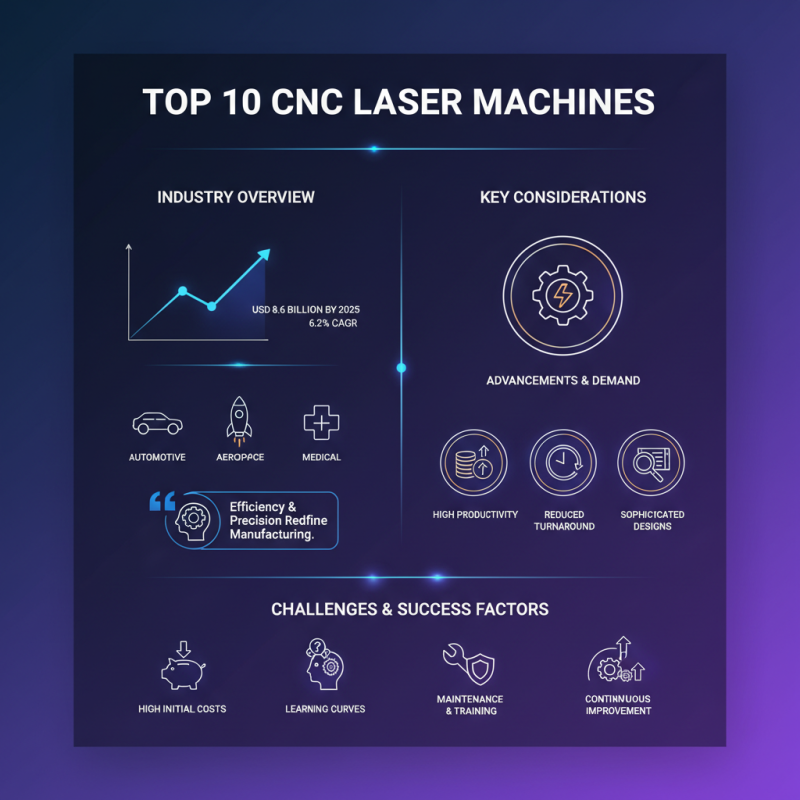

The CNC laser industry is rapidly evolving, driven by advancements in technology and rising demand. According to a report by MarketsandMarkets, the global CNC laser market is expected to reach USD 8.6 billion by 2025, with a CAGR of 6.2%. This growth highlights the significance of CNC laser machines in various sectors, including automotive, aerospace, and medical.

Expert on CNC laser technology, Dr. Emily Chen states, “The efficiency and precision of CNC laser systems redefine manufacturing capabilities.” Her insights reflect the transformative potential of these machines. CNC laser technology not only improves cutting and engraving but also allows for sophisticated design possibilities. Businesses are leveraging this technology to enhance productivity and reduce turnaround times, yet some still encounter challenges with operational inaccuracies.

Investing in CNC laser machines is crucial for staying competitive. However, companies must remain vigilant about maintenance and operator training. The industry continues to face imperfections, including high initial costs and the learning curves associated with advanced systems. Fostering a culture of continuous improvement will be essential to navigate these obstacles effectively.

Types of CNC Laser Machines and Their Applications

CNC laser machines come in various types. Each type has its unique applications and benefits. For instance, CO2 laser machines are popular for cutting and engraving non-metal materials like wood and acrylic. They create smooth edges and intricate designs with high precision.

Fiber laser machines, on the other hand, excel at cutting metals. They can handle materials like stainless steel and aluminum efficiently. The energy efficiency of fiber lasers leads to reduced operational costs. They are fast and suitable for mass production.

However, not all users understand the limits of each machine. CO2 lasers might struggle with thicker metals. Fiber lasers may not work well with some plastics. Choosing the right machine requires careful consideration of specific needs. It's essential to analyze your projects before making a choice.

Top 10 CNC Laser Machines and Their Cutting Speed (in mm/min)

Key Features to Consider When Choosing CNC Laser Machines

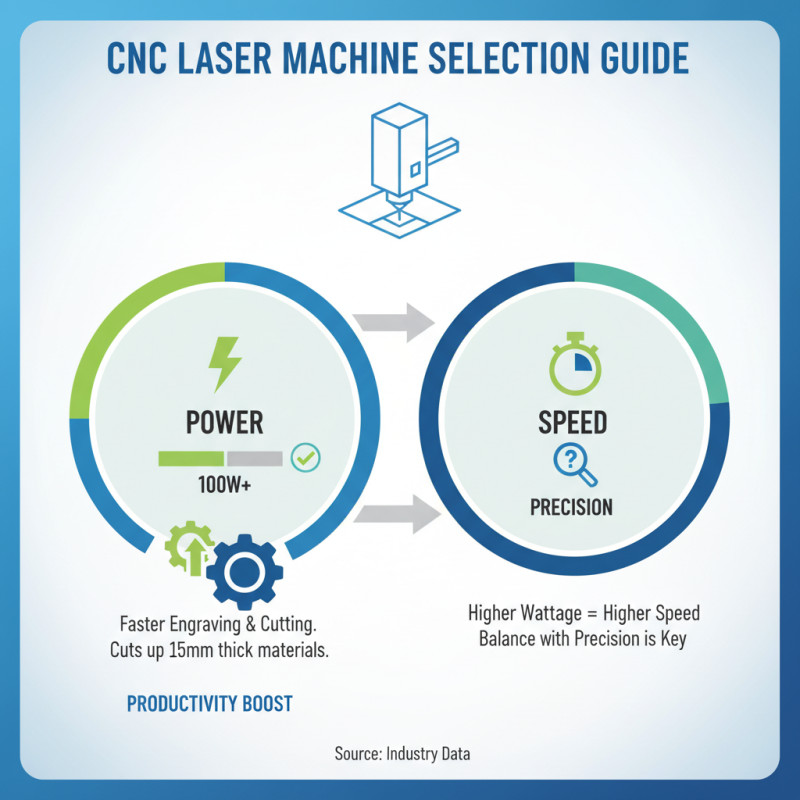

When selecting CNC laser machines, several key features demand attention. Power and speed are critical aspects. A higher wattage translates to faster engraving and cutting speeds. Industry data shows that machines with 100W power can cut through materials up to 15mm thick effectively. This enhances productivity, but does not always guarantee quality. Always consider the balance between power and precision.

Another vital feature is the bed size. A larger working area allows for cutting bigger materials in one go. Many users overlook the importance of this measurement. However, it dictates the maximum project size you can undertake. If a machine is too small, it may lead to multiple setups, wasting valuable time and resources.

User interface plays a significant role as well. Complex interfaces can hinder operations. Reports reveal that user-friendly controls increase operator efficiency by 25%. This can lead to less frustration and better outcomes. Yet, sophistication in software doesn't always bring friendless; complexity can lead to error. An intuitive design minimizes learning curves. Ultimately, while prioritizing these features, it is crucial to reflect on your unique project needs and how the machine fits into your workflow.

Top 10 CNC Laser Machines: Detailed Overview and Specifications

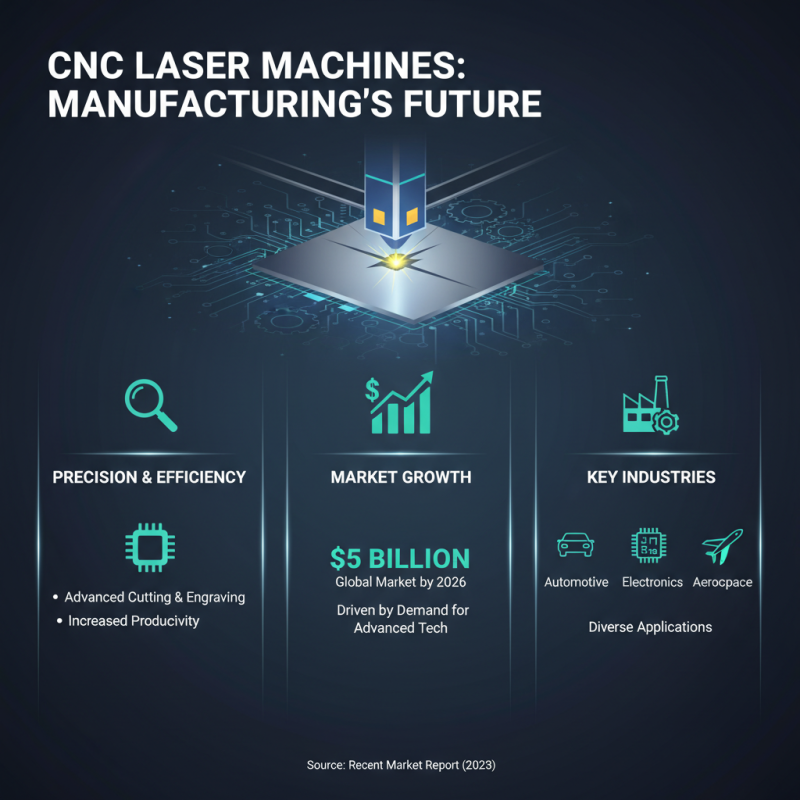

CNC laser machines are pivotal in today's manufacturing landscape. Their precision and efficiency drive productivity across various industries. According to a recent market report, the global CNC laser machine market is expected to reach $5 billion by 2026. This growth reflects the rising demand for advanced cutting and engraving technologies.

When exploring CNC laser machines, one must consider key specifications. Power output, for instance, typically ranges from 40W to 4,000W. High-power laser machines can handle thicker materials. However, the cost increases significantly with power. Not every operation requires the highest wattage. Some applications require delicate touch rather than brute strength.

Additionally, the type of laser technology matters. CO2 lasers excel for cutting non-metallic materials but may fall short on metals. Fiber lasers, though, deliver unmatched speed and precision on metals. Users must assess their specific needs against capabilities. Choices made can lead to expensive miscalculations in workflow efficiency. Not all machines accommodate every material; understanding limitations is crucial to success.

Comparison of Performance and Price Among Leading CNC Laser Models

When evaluating CNC laser machines, performance and price are crucial. The cutting speed, precision, and type of materials can vary greatly. Industry reports indicate that machines with a cutting speed of over 100 inches per minute are becoming standard. They offer a noticeable increase in productivity. However, many users struggle with maintenance issues, leading to unexpected downtimes.

Price also varies significantly. High-performance machines often start above $10,000, while budget options can be found under $5,000. These lower-cost machines might compromise on cutting depth and speed. This creates a dilemma for buyers. Users frequently wish to balance affordability with high-end features. Some machines may display faulty specifications, resulting in unmet expectations.

Moreover, features such as software compatibility often get overlooked during purchases. A machine might boast impressive hardware but lack user-friendly software. Poor software can lead to operational inefficiencies. Industry analysis shows that 40% of users wish they had more software options. This mismatch draws attention to the need for thorough research. Users must evaluate both machine capabilities and software integration before finalizing a purchase.

Top 10 CNC Laser Machines You Must Know About - Comparison of Performance and Price Among Leading CNC Laser Models

| Model | Cutting Area (mm) | Laser Power (W) | Material Compatibility | Price (USD) |

|---|---|---|---|---|

| Model A | 600 x 900 | 80 | Wood, Acrylic | $2,500 |

| Model B | 1200 x 800 | 150 | Metal, Wood | $4,000 |

| Model C | 500 x 500 | 40 | Plastic, Acrylic | $1,500 |

| Model D | 1000 x 1000 | 100 | Wood, Plexiglass | $3,000 |

| Model E | 1300 x 900 | 200 | Metal, Wood | $5,500 |

| Model F | 800 x 600 | 60 | Acrylic, Fabric | $2,000 |

| Model G | 2500 x 1300 | 300 | Metal, Wood, Acrylic | $10,000 |

| Model H | 700 x 1300 | 80 | Wood, Leather | $3,200 |

| Model I | 950 x 600 | 100 | Plastic, Wood | $2,800 |

| Model J | 500 x 800 | 50 | Acrylic | $1,200 |

User Reviews and Expert Insights on Popular CNC Laser Machines

When considering CNC laser machines, user reviews are invaluable. Customers frequently share their hands-on experiences. Some machines excel in precision, making fine cuts effortlessly. Others may fall short in speed or connectivity options. Users often discuss the learning curve. Many find it challenging to master software settings. However, perseverance leads to impressive results.

Expert insights reveal trends in CNC laser technology. Professionals note advances in safety features and efficiency. Some machines now incorporate automatic focusing, which streamlines operations. Yet, not every feature works seamlessly. Instances of software glitches are mentioned. These issues can hinder workflow if not addressed timely.

Price also plays a significant role in decision-making. A machine's cost does not always correlate with quality or performance. It's essential to analyze user feedback. Some budget options perform well for hobbyists. Others may disappoint in a professional setting. Evaluating both user and expert opinions can guide potential buyers to make informed choices.

Related Posts

-

Top 5 Reasons to Invest in a CNC Laser Cutter for Your Business

-

What is a CNC Laser Cutter and How Does it Work for Your Projects

-

What is a CNC Laser Cutter? Benefits, Uses, and How It Works Explained

-

Top 10 CNC Cutting Techniques for Precision and Efficiency in Manufacturing

-

How to Choose the Right Laser CNC Machine for Your Projects

-

Top 10 Benefits of Alpha Laser Technology You Need to Know

Machine models and specifications are subject to change without notice.